Hello all. I'm new to this forum and also relatively new to all things electrical. My understanding is fairly basic but I have been trying to self educate myself as best possible.

I am currently working on organizing the wiring for my auxiliary lighting on my 2018 4Runner and I have put together a schematic to summarize my ideas. There are a couple things I would like to achieve:

1. Organize all the wires in the engine bay and behind the dash. Currently it is a mess of various individual relay harnesses that came with lighting kits (each having their own battery connections). I have come a long way since I started this electrical journey and I now have the proper skills and tools to crimp connections and properly size wires.

2. Maintain a factory/OEM look without splicing into factory wiring or disturbing any of the original systems. So far I have been able to do this by using fuse taps and factory connector harnesses.

3. Be able to trigger my auxiliary lights with a flick of the steering wheel stalk (high beam trigger) AND individually with their own switches. This has been the more challenging aspect of this project and what I am mainly looking for input on (double relay solution presented in wiring schematic).

Apologies for the lengthy first post but hopefully this gets all the info across. Feel free to skip to my schematic but I appreciate any help, guidance, suggestions, or other. Thank you in advance!

Background

The 5th generation 4Runner has a combined Daytime Running Light (DRL) and high beam circuit which powers a halogen bulb. Toyota decided to use the full 12 volts to trigger the high beams and they reduce the voltage to about 9.6 volts to run the DRL with a PWM (pulse width modulation) signal. I am very new to PWM and I have no way to test/detect it. I understand PWM pulses an electrical current very quickly to limit the brightness of the bulb. Most owners decide to switch out the halogen bulbs for LEDs and report flickering when in DRL mode. I was able to find a set of LED bulbs that include a module/driver to eliminate the flickering (no idea how that works).

Over on the 4Runner forums, a member started a thread on filtering the PWM to use the high beam trigger (here is a link to that thread if anyone is interest). The issue they encountered was a flickering/rattling relay from the PWM signal. The original poster has moved on to other projects but he provided some good info, one of which lead me to this forum (https://www.electro-tech-online.com/threads/filtering-pwm-on-12v-circuit.128439/). This was a very helpful thread and I hope to implement the PWM filter if necessary. Unfortunately, I have not personally experienced the PWM signal and when testing an automotive relay, it did not flicker for me. But I noticed the relay was triggered for both the 12V high beam voltage and the 9.6V DRL voltage, meaning I could not simply tap into the high beam circuit for a signal.

Current Solution

I found a Reddit post discussing the high beam circuit which lead me to a low voltage cutoff module. I did not like the idea of the voltage display on that specific module, draining my battery (high beam fuse reads 0.05V even when the vehicle is off), therefore I found one without a display. I ordered one up and it seems to activate when the high beams are triggered and is off when the DRLs are on. I think the voltage trigger issue is solved but I'm not sure if the PWM will give me issues. The last thing I want is for the pulses to rattle the module or my other relays and reduce their lifespan or worse (can it damage the system?). I have incorporated the low current module into my wiring schematic but I'm not sure if the PWM filter is needed, where it would be needed (before/after the module), or how to wire it up. I plan to use a project box to house the module and maybe I can fit the filter along with it, depending on the assembly.

Questions

That brings me to a few questions. Now that I have convinced myself with a wiring schematic that this is feasible, I wanted to get a second set of eyes to give me feedback. I also have a few questions/concerns that stem from my lack of knowledge on electrical systems.

1. I drew up the PWM filter connected to the high beam fuse (with a fuse tap) and before the low voltage cutoff module. Is this the correct location? Is it acceptable to use the same ground for the filter and the module?

2. I am fairly confident in my crimping abilities but soldering is still relatively new/difficult. I understand the filter components (diode and capacitor) should be soldered to the system. Can these be soldered to automotive stranded wire? Is there a way to get a reliable crimp connection? Does anyone have any exampled of these components in a real world application (as opposed to a pcb board)?

3. My double relay solution should allow me to use the high beam trigger to operate my auxiliary lights with the high beams or independently. Both relays will provide power to the individual lighting switches through a single wire ("Y" connection at the wires). I drew in diodes right before the "Y" splice to prevent backflow of electricity. Are these needed? I don't think the relays will ever be running power at the same time, but I'm not sure how the system would react if the diodes were not there. This is definitely an issue with my lack of knowledge on electrical systems and components but hopefully a simple question for someone here.

4. A general sanity check. Does this system make sense? Are there any aspects I am neglecting or overlooking? Any other suggestions or ideas I should consider?

Again, I apologize for the long winded post but I think this summarizes my project and hopefully gives enough information for you all to provide feedback and answers. Let me know if there is anything I forgot to include. And now onto some pictures/diagrams:

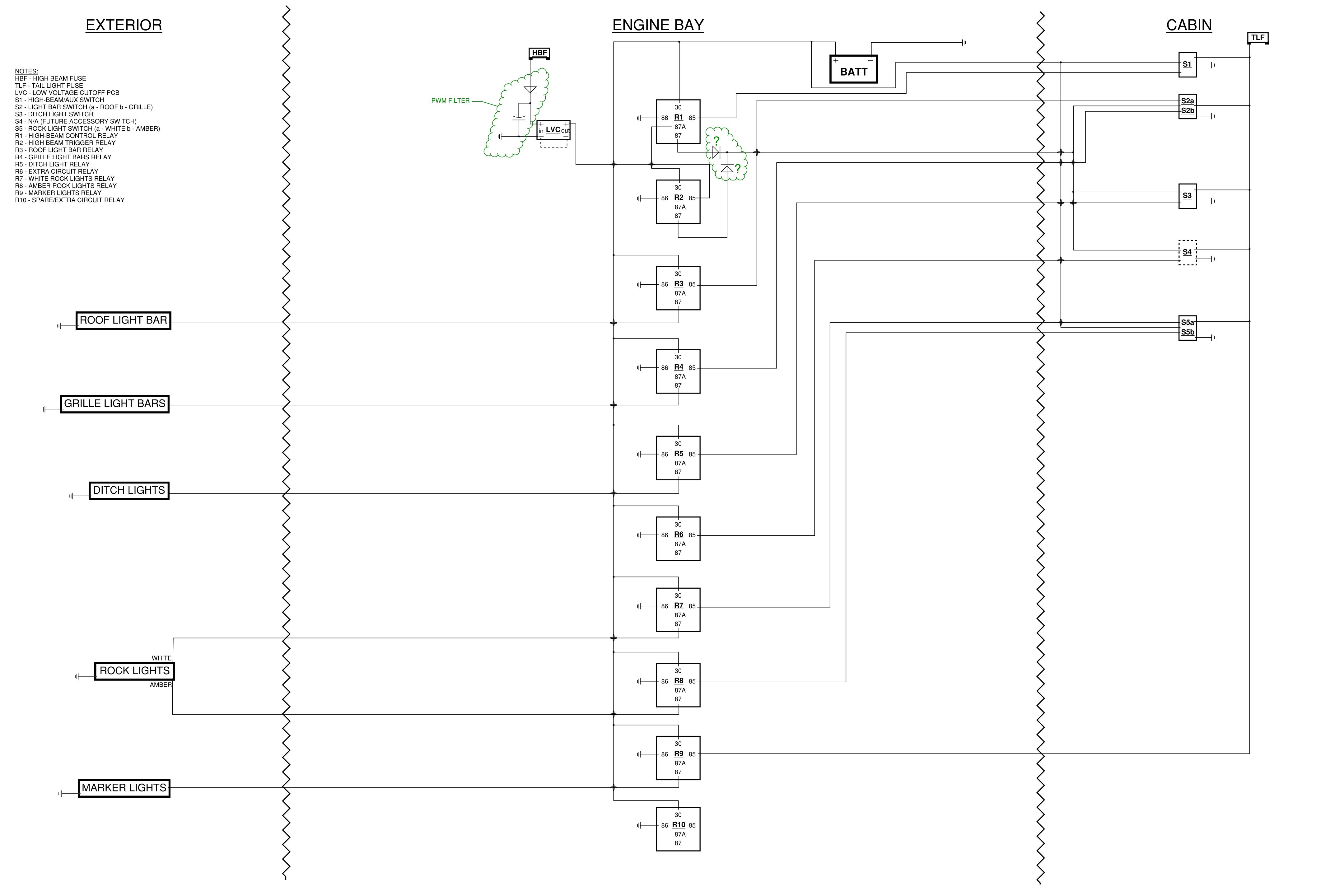

Here is an image of my schematic diagram. It is a bit lower resolution but I bubbled the question areas in green for visual identification. I am also attaching a PDF of the diagram (in its original color glory) which should be a higher resolution. Note, this was not created with an electrical software, but instead with a PDF editor that I have handy. Please excuse my lack of drafting abilities. Hopefully it portrays my ideas. (note: the wire crosses are indicated with double ovals and the "T" connections are indicated with a circle/dot)

I am currently working on organizing the wiring for my auxiliary lighting on my 2018 4Runner and I have put together a schematic to summarize my ideas. There are a couple things I would like to achieve:

1. Organize all the wires in the engine bay and behind the dash. Currently it is a mess of various individual relay harnesses that came with lighting kits (each having their own battery connections). I have come a long way since I started this electrical journey and I now have the proper skills and tools to crimp connections and properly size wires.

2. Maintain a factory/OEM look without splicing into factory wiring or disturbing any of the original systems. So far I have been able to do this by using fuse taps and factory connector harnesses.

3. Be able to trigger my auxiliary lights with a flick of the steering wheel stalk (high beam trigger) AND individually with their own switches. This has been the more challenging aspect of this project and what I am mainly looking for input on (double relay solution presented in wiring schematic).

Apologies for the lengthy first post but hopefully this gets all the info across. Feel free to skip to my schematic but I appreciate any help, guidance, suggestions, or other. Thank you in advance!

Background

The 5th generation 4Runner has a combined Daytime Running Light (DRL) and high beam circuit which powers a halogen bulb. Toyota decided to use the full 12 volts to trigger the high beams and they reduce the voltage to about 9.6 volts to run the DRL with a PWM (pulse width modulation) signal. I am very new to PWM and I have no way to test/detect it. I understand PWM pulses an electrical current very quickly to limit the brightness of the bulb. Most owners decide to switch out the halogen bulbs for LEDs and report flickering when in DRL mode. I was able to find a set of LED bulbs that include a module/driver to eliminate the flickering (no idea how that works).

Over on the 4Runner forums, a member started a thread on filtering the PWM to use the high beam trigger (here is a link to that thread if anyone is interest). The issue they encountered was a flickering/rattling relay from the PWM signal. The original poster has moved on to other projects but he provided some good info, one of which lead me to this forum (https://www.electro-tech-online.com/threads/filtering-pwm-on-12v-circuit.128439/). This was a very helpful thread and I hope to implement the PWM filter if necessary. Unfortunately, I have not personally experienced the PWM signal and when testing an automotive relay, it did not flicker for me. But I noticed the relay was triggered for both the 12V high beam voltage and the 9.6V DRL voltage, meaning I could not simply tap into the high beam circuit for a signal.

Current Solution

I found a Reddit post discussing the high beam circuit which lead me to a low voltage cutoff module. I did not like the idea of the voltage display on that specific module, draining my battery (high beam fuse reads 0.05V even when the vehicle is off), therefore I found one without a display. I ordered one up and it seems to activate when the high beams are triggered and is off when the DRLs are on. I think the voltage trigger issue is solved but I'm not sure if the PWM will give me issues. The last thing I want is for the pulses to rattle the module or my other relays and reduce their lifespan or worse (can it damage the system?). I have incorporated the low current module into my wiring schematic but I'm not sure if the PWM filter is needed, where it would be needed (before/after the module), or how to wire it up. I plan to use a project box to house the module and maybe I can fit the filter along with it, depending on the assembly.

Questions

That brings me to a few questions. Now that I have convinced myself with a wiring schematic that this is feasible, I wanted to get a second set of eyes to give me feedback. I also have a few questions/concerns that stem from my lack of knowledge on electrical systems.

1. I drew up the PWM filter connected to the high beam fuse (with a fuse tap) and before the low voltage cutoff module. Is this the correct location? Is it acceptable to use the same ground for the filter and the module?

2. I am fairly confident in my crimping abilities but soldering is still relatively new/difficult. I understand the filter components (diode and capacitor) should be soldered to the system. Can these be soldered to automotive stranded wire? Is there a way to get a reliable crimp connection? Does anyone have any exampled of these components in a real world application (as opposed to a pcb board)?

3. My double relay solution should allow me to use the high beam trigger to operate my auxiliary lights with the high beams or independently. Both relays will provide power to the individual lighting switches through a single wire ("Y" connection at the wires). I drew in diodes right before the "Y" splice to prevent backflow of electricity. Are these needed? I don't think the relays will ever be running power at the same time, but I'm not sure how the system would react if the diodes were not there. This is definitely an issue with my lack of knowledge on electrical systems and components but hopefully a simple question for someone here.

4. A general sanity check. Does this system make sense? Are there any aspects I am neglecting or overlooking? Any other suggestions or ideas I should consider?

Again, I apologize for the long winded post but I think this summarizes my project and hopefully gives enough information for you all to provide feedback and answers. Let me know if there is anything I forgot to include. And now onto some pictures/diagrams:

Here is an image of my schematic diagram. It is a bit lower resolution but I bubbled the question areas in green for visual identification. I am also attaching a PDF of the diagram (in its original color glory) which should be a higher resolution. Note, this was not created with an electrical software, but instead with a PDF editor that I have handy. Please excuse my lack of drafting abilities. Hopefully it portrays my ideas. (note: the wire crosses are indicated with double ovals and the "T" connections are indicated with a circle/dot)