shimniok

Member

Thanks in advance for your time. I'm a hobbyist, CompE degree from '93. I am interested in selecting a complimentary power MOSFET IC -- in h-bridge config -- to drive a 3V hobby motor via Microcontroller.

Hopefully someone can check my selection process. I've spent some time reviewing Sedra & Smith, looking at a few websites on motor drivers and mosfets, and reading a couple of app notes explaining MOSFET datasheet curves.

At this point, I am looking for input on my in-development heuristic for selecting an appropriate MOSFET given battery and motor specifications.

Motor: let's pick this Mabuchi FA-30-RA-18100 hobby motor for sake of argument. 2.1A stall current, 0.56A max efficiency. 1.5V - 3.0V DC operating range.

Power Supply: Also, let's say I am going to use 2 x AA alkaline batteries (as I understand, 3.0V charged, 2.0V depleted). Microcontroller will run off 1.8V-5.5V. So logic level out will range from 2V - 3V.

I'd like to keep parts count down, so driving gate directly from MCU is preferred over using MOSFET driver. I'd like to permit either PWM or continuous. I would run a fairly low PWM frequency (my thinking being that it would, I hope, reduce gate capacitance current draw? and make gate charge/capacitance issues less important in selection?)

My heuristic so far is...

1. Find MOSFETS rated well over 2A for N and P and Vgs(th) comfortably less than 2V.

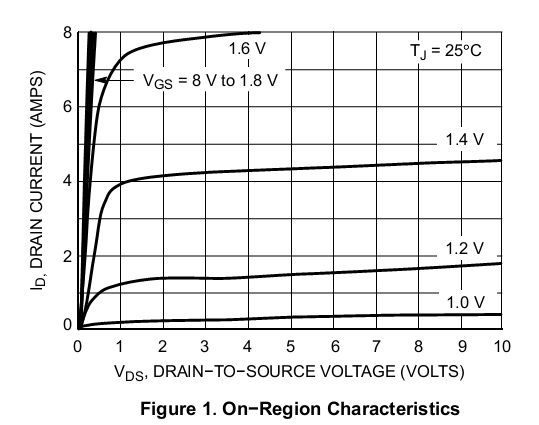

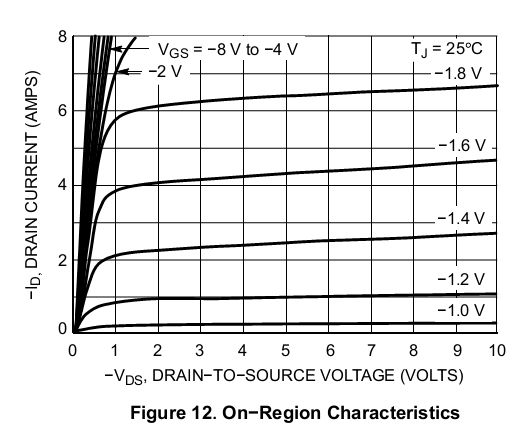

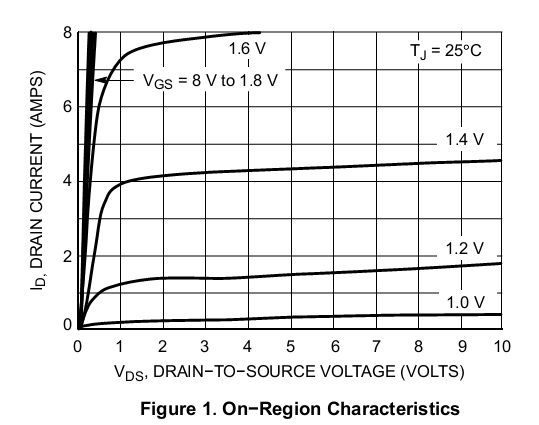

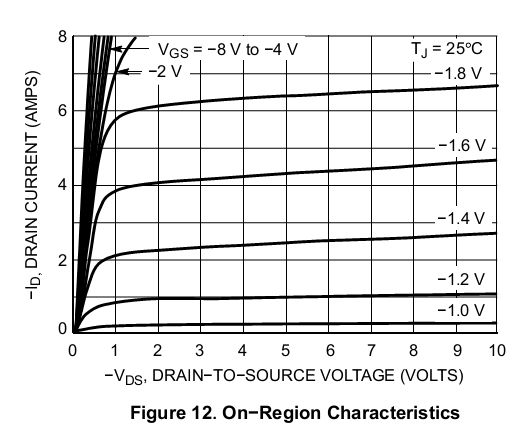

2. Of those, look for MOSFETs with Id / Vds curves such that MOSFET will operate in triode region for expected operating current and voltage.

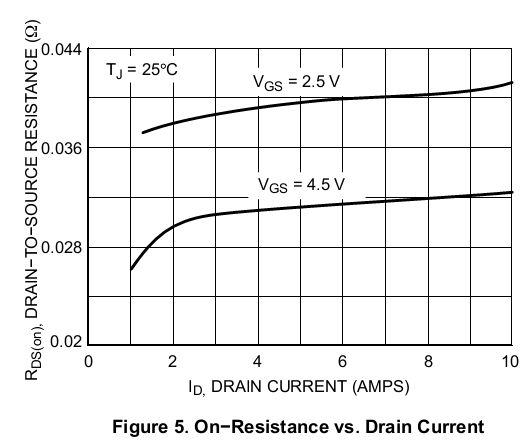

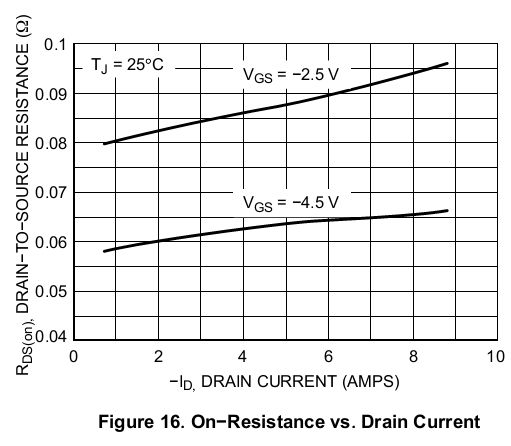

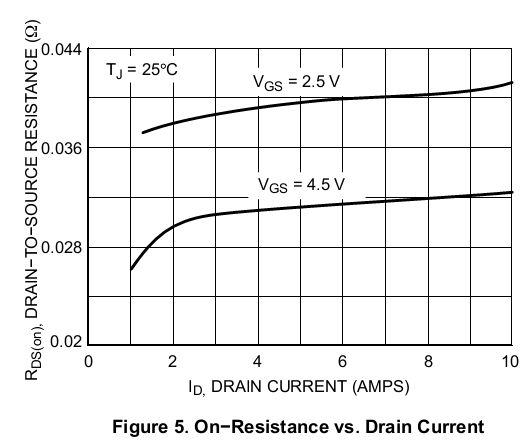

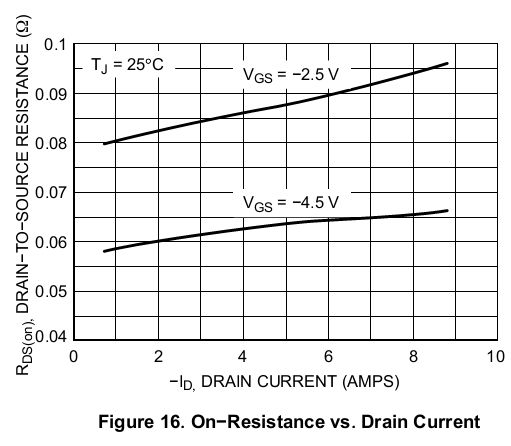

3. Of those, look for MOSFETs with lowest Rds(on) at the desired operating range.

Example... after sifting through various options and learning my best how to read the various curves... I come up with one possibility (of several)

On Semi, NTHD3102C (Datasheet, pdf) Images below reproduced for educational purposes.

Basic ratings are Vgs(th) = 1.2V; 4A (N), 5.5A < 5sec; 3.1A (P), 4.2A < 5 sec. So given a stall current of about 2A this should be entirely adequate. (and even drive other motors with higher stall current).

The Id vs Vds curve shows that at Vgs = 2V and up, the N and P MOSFETS should be in triode region for Id=2A with Vds < 0.5Ω

Unfortunately the datasheet doesn't show a Vgs vs Rds(on) curves as do the Vishay sheets I've looked at. Seems like that would be helpful.

However, if I look at the Id vs Rds(ON) for N and P it looks like the operating point will have Rds(on) at the low end of the scale.

I see an Rds(on) vs Id for Vgs=2.5V and various Tj values. The Rds(on) values all look tiny to me.

On characteristics section shows Rds(ON) of -- guessing based on numbers -- of probably < 100mΩ for 2V / Id=2A.

What other charts should I consider?

Again thanks for your patience and time and help.

Michael

Hopefully someone can check my selection process. I've spent some time reviewing Sedra & Smith, looking at a few websites on motor drivers and mosfets, and reading a couple of app notes explaining MOSFET datasheet curves.

At this point, I am looking for input on my in-development heuristic for selecting an appropriate MOSFET given battery and motor specifications.

Motor: let's pick this Mabuchi FA-30-RA-18100 hobby motor for sake of argument. 2.1A stall current, 0.56A max efficiency. 1.5V - 3.0V DC operating range.

Power Supply: Also, let's say I am going to use 2 x AA alkaline batteries (as I understand, 3.0V charged, 2.0V depleted). Microcontroller will run off 1.8V-5.5V. So logic level out will range from 2V - 3V.

I'd like to keep parts count down, so driving gate directly from MCU is preferred over using MOSFET driver. I'd like to permit either PWM or continuous. I would run a fairly low PWM frequency (my thinking being that it would, I hope, reduce gate capacitance current draw? and make gate charge/capacitance issues less important in selection?)

My heuristic so far is...

1. Find MOSFETS rated well over 2A for N and P and Vgs(th) comfortably less than 2V.

2. Of those, look for MOSFETs with Id / Vds curves such that MOSFET will operate in triode region for expected operating current and voltage.

3. Of those, look for MOSFETs with lowest Rds(on) at the desired operating range.

Example... after sifting through various options and learning my best how to read the various curves... I come up with one possibility (of several)

On Semi, NTHD3102C (Datasheet, pdf) Images below reproduced for educational purposes.

Basic ratings are Vgs(th) = 1.2V; 4A (N), 5.5A < 5sec; 3.1A (P), 4.2A < 5 sec. So given a stall current of about 2A this should be entirely adequate. (and even drive other motors with higher stall current).

The Id vs Vds curve shows that at Vgs = 2V and up, the N and P MOSFETS should be in triode region for Id=2A with Vds < 0.5Ω

Unfortunately the datasheet doesn't show a Vgs vs Rds(on) curves as do the Vishay sheets I've looked at. Seems like that would be helpful.

However, if I look at the Id vs Rds(ON) for N and P it looks like the operating point will have Rds(on) at the low end of the scale.

I see an Rds(on) vs Id for Vgs=2.5V and various Tj values. The Rds(on) values all look tiny to me.

On characteristics section shows Rds(ON) of -- guessing based on numbers -- of probably < 100mΩ for 2V / Id=2A.

What other charts should I consider?

Again thanks for your patience and time and help.

Michael