Gents,

forgive a second thread so quickly after the previous one, but I can't seem to crack this on my own. I wanted to use the TMR0 in the 16F887 to toggle an output for a very short period of time (20us), effectively creating a pulse. I thought interrupts would be perfect for this, but after an hour or so messing around with a scope and some test code, I can't seem to get the timings right. Here's the code I used for tests:

All the above does is wait for an interrupt from the TMR0 and change the state of pin RE0. Now here's a screenshot from the scope, connected to RE0:

**broken link removed**

As you can see it shows 283us between changes on RE0. Loading the timer with 0 and assigning to WDT means prescale of 1:1, so I would expect a change of state on RE0 every 255-256us, not 283us. That is a 27us error, rather big considering that I want a 20us pulse.

I've also popped the code into MPLAB Sim and timed it using a breakpoint and stopwatch. Again, identical result, 283us.

I'm surprised as I've got a PWM output, which I've checked with a scope and it's bang on precise, here's what I use:

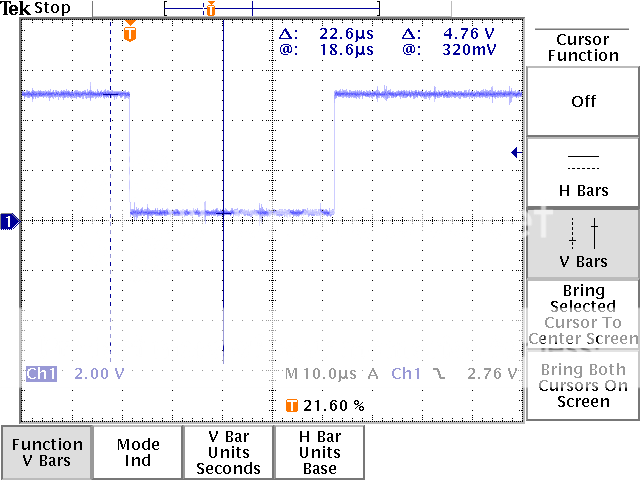

Looking at the scope and what's produced by the PIC on RC2, I get a period of 623.6us and a pulse width of exactly 32us:

**broken link removed**

Does anyone know where the errors might be coming from? the code is stripped to bare minimum, but I still get the dreaded 20 odd us errors on whatever value I preload TMR0 with.

Regards,

T.

forgive a second thread so quickly after the previous one, but I can't seem to crack this on my own. I wanted to use the TMR0 in the 16F887 to toggle an output for a very short period of time (20us), effectively creating a pulse. I thought interrupts would be perfect for this, but after an hour or so messing around with a scope and some test code, I can't seem to get the timings right. Here's the code I used for tests:

Code:

void

main(void)

{

// initiate registers here used in the main code which I've deleted for testing the TMR0 interrupts

TRISE0 = 0; // configured as output

ANS0 = 0;

// internal OSC - 4Mhz

OSCCON = 0b01100101;

TMR0 = 0; //test tmr0 ints

INTCON = 0b10100000;

OPTION_REG = 0b00001000;

while(1) //Do this for loop forever!

{

} // end of global loop

} // end of main()

void interrupt ISR()

{

if (T0IF)

{

T0IF = 0; //clear flag

RE0 = !RE0; //toggle the output

TMR0 = 0; //reset timer

}

if (INTF)

{

//this code is for RB0 interrupts which I've disabled for testing the TMR0 interrupts

}

}All the above does is wait for an interrupt from the TMR0 and change the state of pin RE0. Now here's a screenshot from the scope, connected to RE0:

**broken link removed**

As you can see it shows 283us between changes on RE0. Loading the timer with 0 and assigning to WDT means prescale of 1:1, so I would expect a change of state on RE0 every 255-256us, not 283us. That is a 27us error, rather big considering that I want a 20us pulse.

I've also popped the code into MPLAB Sim and timed it using a breakpoint and stopwatch. Again, identical result, 283us.

I'm surprised as I've got a PWM output, which I've checked with a scope and it's bang on precise, here's what I use:

Code:

PR2 = 38; //this means PWM period of 624us

CCP1CON = 0b00001100;

CCPR1L = 0b00000010; //set to 2, so pulse width is 2 x 16 = 32 with 16 prescaler

T2CON = 0b00000110; // Prescaler set to 16 on startup, TMR2 ON, Postscaler 1:1Looking at the scope and what's produced by the PIC on RC2, I get a period of 623.6us and a pulse width of exactly 32us:

**broken link removed**

Does anyone know where the errors might be coming from? the code is stripped to bare minimum, but I still get the dreaded 20 odd us errors on whatever value I preload TMR0 with.

Regards,

T.