embedded_sys

Member

I'm working with a system that requires me to read 120VAC inputs on a pivot irrigation system. The wires travel 1/4 of a mile. Occasionally on the line I am reading, the voltage is 65VAC instead of 120VAC. I believe this is an induced voltage because of the length of the wires. I only want to know when the line is 120VAC. I'm using a simple opto-coupler with a resistor to detect the voltage. At 65VAC, my micro-controller reads high. How can I adjust my circuit (or redesign it) to detect only voltage about 100VAC? I've tried increasing the value of R14 so that it only turns on the LED above 100VAC, but at 120VAC, the input reads high and low intermittently. I need to know exactly when the line has 120VAC on it and never anything less. I've used this module before with success, but at $11+ it is too expensive. It has a voltage range of 90-140VAC.

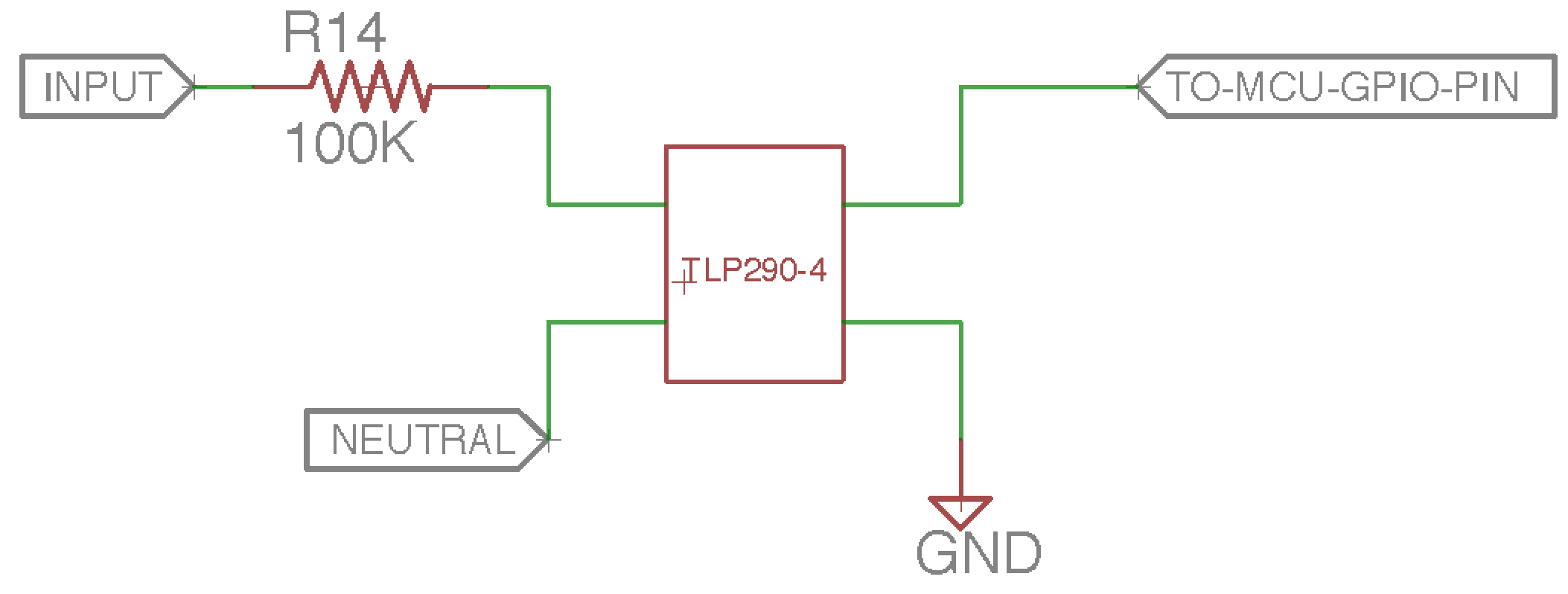

Below I have the current components I use and the schematic.

Opto Isolator TLP290-4

100K Resistor

Below I have the current components I use and the schematic.

Opto Isolator TLP290-4

100K Resistor