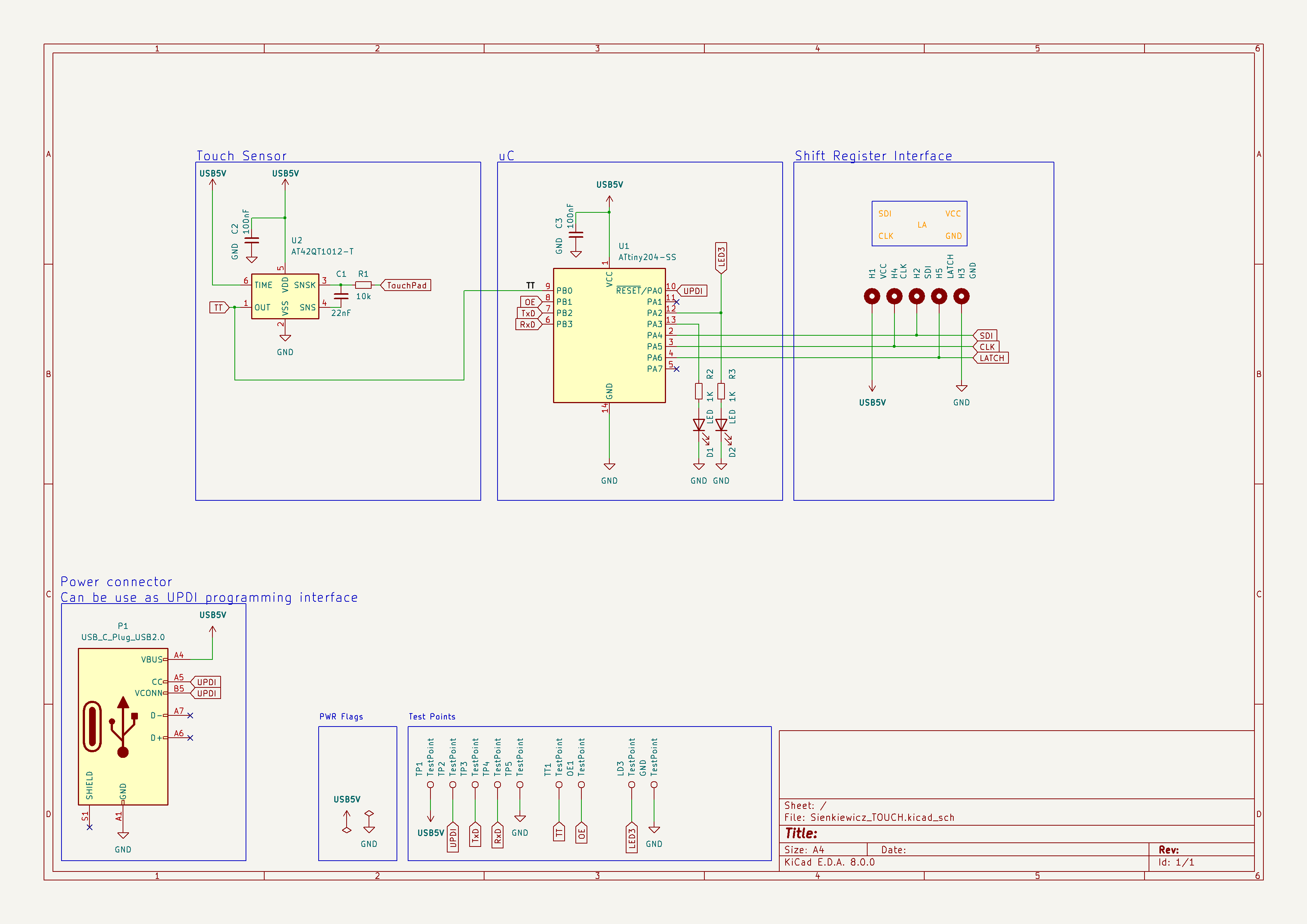

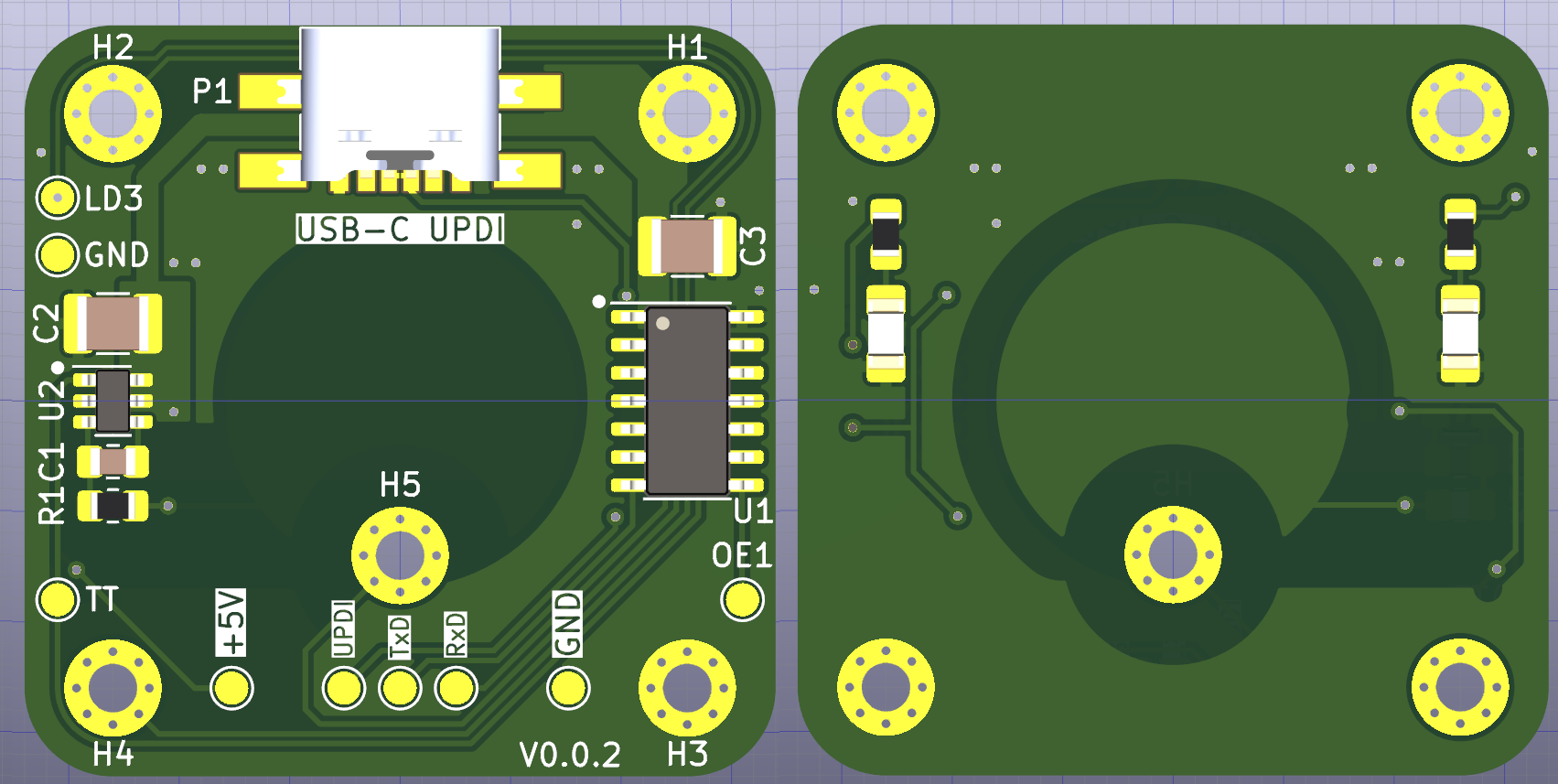

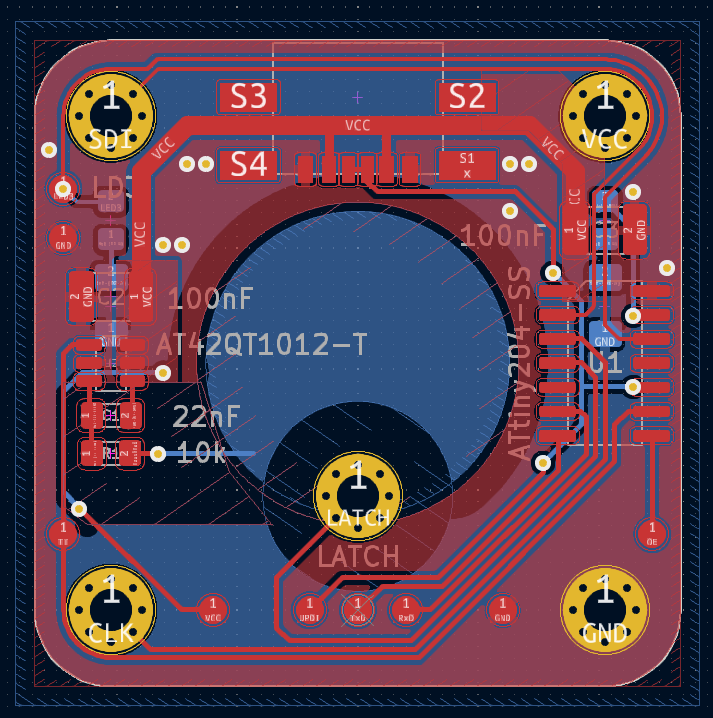

I designed a simple PCB for learning purposes. It consists of a touch sensor, Attiny microcontroller, and two LEDs. I have already soldered the PCB. I was able to program the Attiny microcontroller easily using MPLAB X IDE. I can control my two LEDs on the bottom side, but the touch sensor is not working correctly.

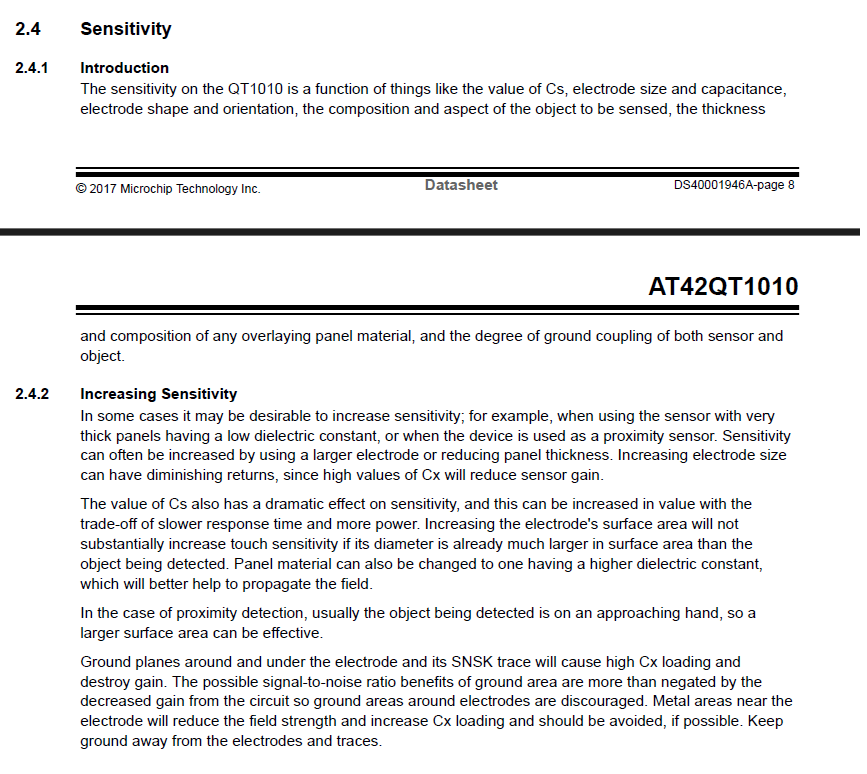

I would like to ask if I haven't made any major mistakes in the touch sensor area. I have attached the project in KiCad 8 and the datasheet for AT42QT1012

Best Regards,

Pawel

I would like to ask if I haven't made any major mistakes in the touch sensor area. I have attached the project in KiCad 8 and the datasheet for AT42QT1012

Best Regards,

Pawel