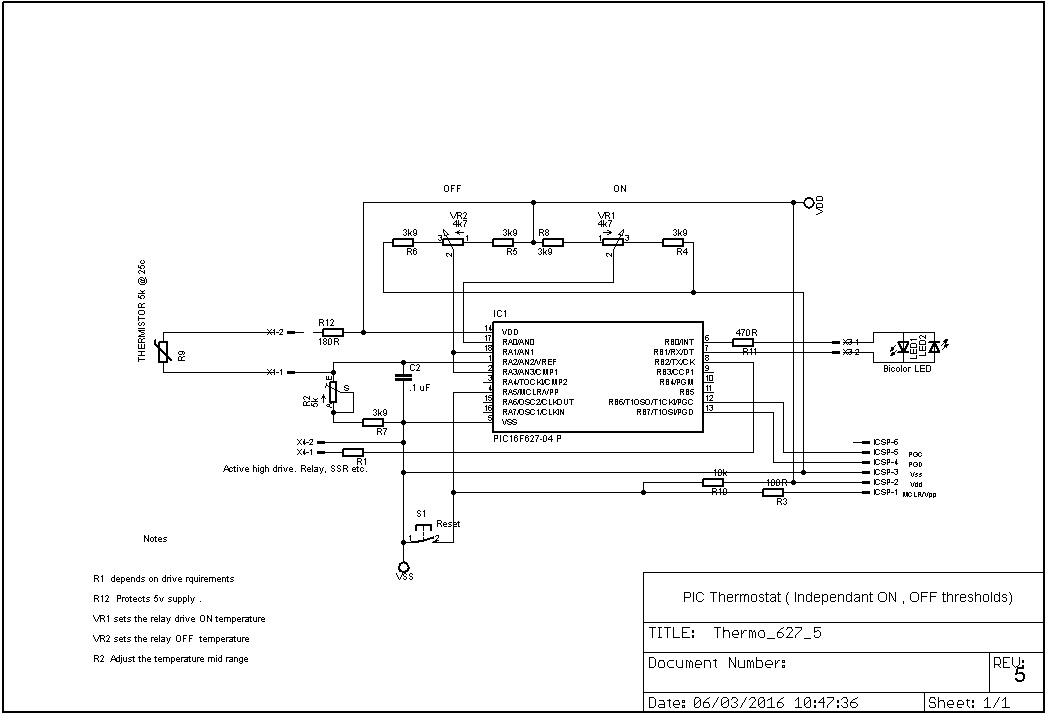

I always thought the standard , bi-metal thermostat devices have too much hysteresis for some of my requirements, for instance, a seed propagator ideally requires a steady temperature for germination , also I wanted a control for a bathroom extractor fan to run when the power shower was used , but not attached to the light switch by using a sensor attached to to the shower hot supply also something for the Green house heat / ventilation . This circuit , uses a NTC thermistor as a sensor ,inputting to the PIC16F627 comparators the adjustment side is determined by VR1 ,VR2 potential dividers , thus setting the ON and OFF temperatures independently, so giving an active Cooling (LED green) or heating (LED red ) thermostat, with very close hysteresis , the bicolor led flashes when drive is active. the signal at R1 can be used to switch an SST or a transistor / relay circuit. The addition of a digital temperature readout would enhance its uses.

hex file for PIC16F627. ....

hex file for PIC16F627. ....

Attachments

Last edited: