Boncuk

New Member

Hi,

I intend to air condition my entire house which involves a lot of room fans for equal air distribution.

The fans I can purchase here are high rpm high power types, far too loud at nominal power. Reducing fan speed with a phase contol unit would solve only a part of the problem. The ON/OFF cycles are controlled by a MASTER controller and the rpm regulation, done with normal (modified) dimmers should be left to individuals in the rooms. Setting the fan speed too low the fan won't start from a full stop and hence burn up with current flow and no rotation.

So I thought about the possibility employing a small µc which can be set to output a signal high enough to safely start the motor at any condition.

A safe start-up voltage for the fans is 130V (mains 230V).

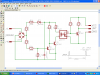

I made up a zero-crossing-unit to be used for an interrupt in a µc, gaining the zero-crossing point without transformer (which can already cause a phase shift). The circuit output is a TTL compatible high pulse of 50 to 200µs duration every 10ms at zero crossing

My knowledge concerning µcs is very poor, not to say lousy.

What the controller should be able to do: Accept up and down key inputs to increase/decrease output pulse lengths based on the interrupt input to control the triac circuit. Have a three bit preselection speed setup (for output voltages 130,140 and 150V) to be set by two jumpers. Minumum setting via keys always to the preselected speed (voltage).

Here is the schematic of the zero-crossing circuit.

I would very much appreciate if somebody can take the time to make a source code (PIC or ATMEL) for me. I hope I can do the rest on my own.

Thanks for your attention

Regards

Hans

I intend to air condition my entire house which involves a lot of room fans for equal air distribution.

The fans I can purchase here are high rpm high power types, far too loud at nominal power. Reducing fan speed with a phase contol unit would solve only a part of the problem. The ON/OFF cycles are controlled by a MASTER controller and the rpm regulation, done with normal (modified) dimmers should be left to individuals in the rooms. Setting the fan speed too low the fan won't start from a full stop and hence burn up with current flow and no rotation.

So I thought about the possibility employing a small µc which can be set to output a signal high enough to safely start the motor at any condition.

A safe start-up voltage for the fans is 130V (mains 230V).

I made up a zero-crossing-unit to be used for an interrupt in a µc, gaining the zero-crossing point without transformer (which can already cause a phase shift). The circuit output is a TTL compatible high pulse of 50 to 200µs duration every 10ms at zero crossing

My knowledge concerning µcs is very poor, not to say lousy.

What the controller should be able to do: Accept up and down key inputs to increase/decrease output pulse lengths based on the interrupt input to control the triac circuit. Have a three bit preselection speed setup (for output voltages 130,140 and 150V) to be set by two jumpers. Minumum setting via keys always to the preselected speed (voltage).

Here is the schematic of the zero-crossing circuit.

I would very much appreciate if somebody can take the time to make a source code (PIC or ATMEL) for me. I hope I can do the rest on my own.

Thanks for your attention

Regards

Hans

Attachments

Last edited: