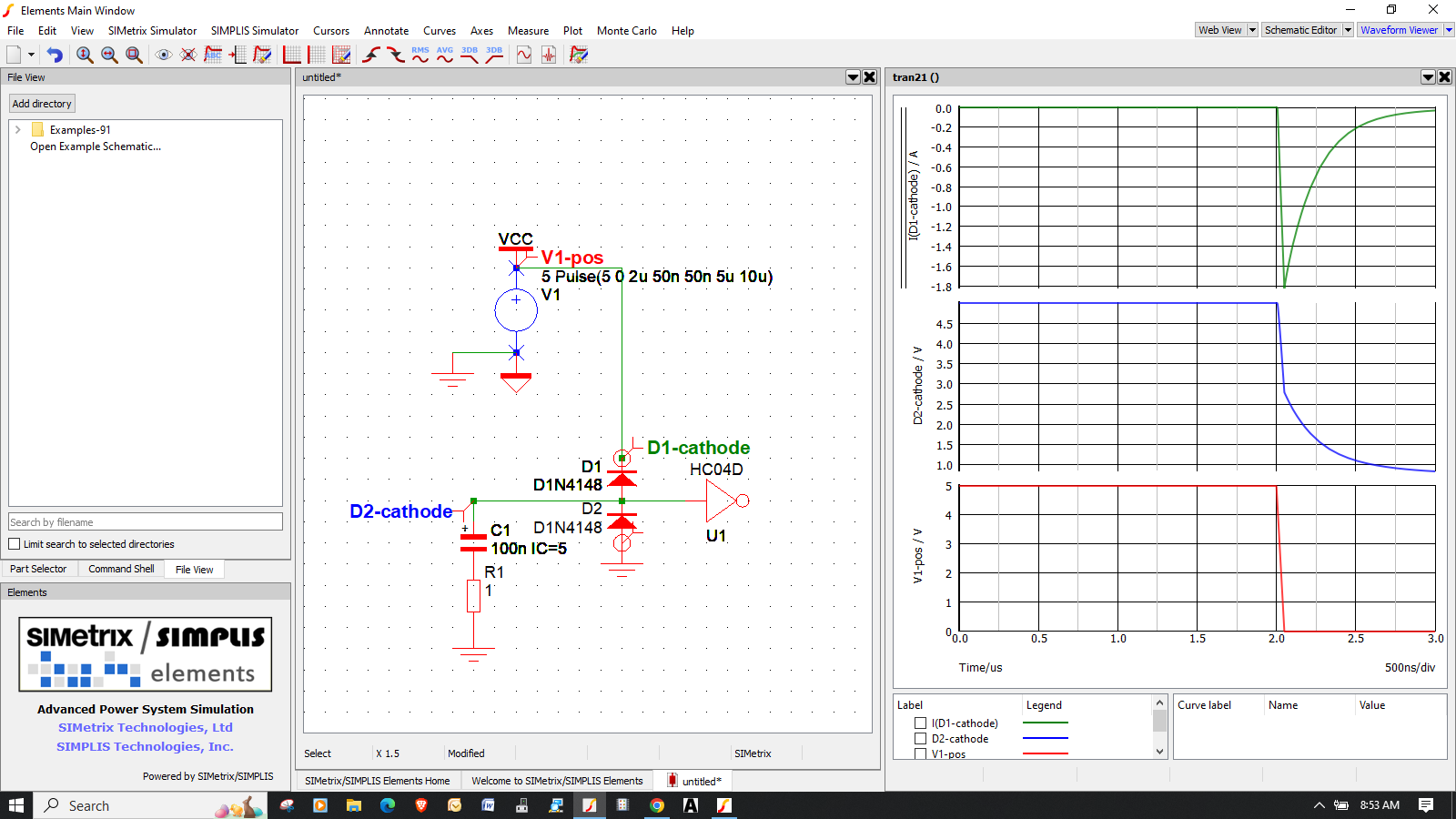

Folks seem to like building delays, debounce keys, etc, by placing large C at the

inputs to CMOS gates.

NOT A GOOD IDEA

For case where supply collapse rapid due to its design, load situation.

TI confirms this in an ap note on general CMOS usage. Here is a rough sim of the problem.

Note since spice model did not have the parasitic diodes in it I used external as substitute.

Also used 1 ohm as C ESR......roll your own value(s) for your case. Note using .1 ohms for

C ESR produced 3A thru D1......

The simple way around this is to place a series R between gate input and the large C.

Regards, Dana.

inputs to CMOS gates.

NOT A GOOD IDEA

For case where supply collapse rapid due to its design, load situation.

TI confirms this in an ap note on general CMOS usage. Here is a rough sim of the problem.

Note since spice model did not have the parasitic diodes in it I used external as substitute.

Also used 1 ohm as C ESR......roll your own value(s) for your case. Note using .1 ohms for

C ESR produced 3A thru D1......

The simple way around this is to place a series R between gate input and the large C.

Regards, Dana.

Last edited: