The_Schnebbz

New Member

Greetings all,

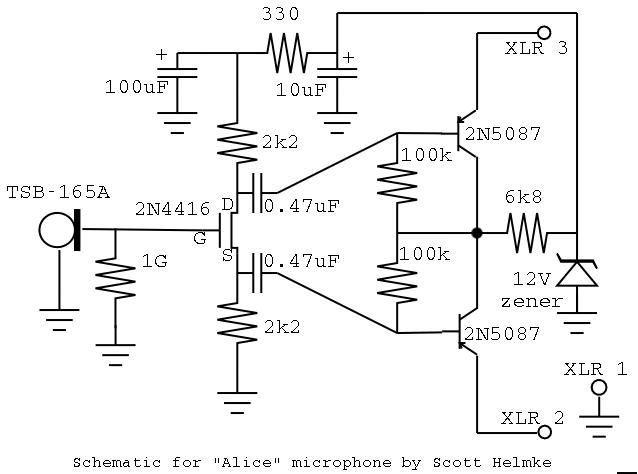

I'm currently attempting to build a microphone in the same style as [Scott Helmke's "Alice"] mic. Following the parts list and schematic that they've posted to their website.

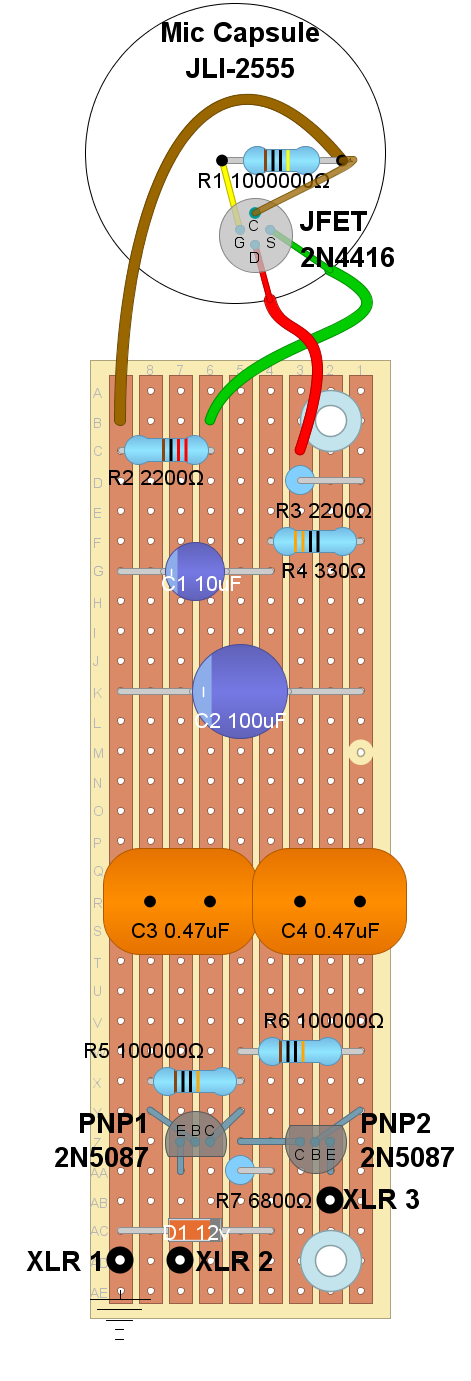

Given that this is the first electronics DIY project I'm attempting (the wisdom of using this as a first project is yet to be seen.) I'd appreciate anyone looking over how I've translated from the schematic to a stripboard to make sure I haven't made any silly mistakes. (And of course any applicable advice is welcome as well.)

The schematic I worked from (from Scott Helmke's website)

And how I laid the above out in DIYLC

(If it makes a meaningful difference, Mouser was out of specifically the 2N4416 JFETs at the time, so the one I actually have on hand is the 2N4416A variant. Here's a [Link] to the datasheet from Mouser, the difference I'm seeing is the breakdown voltage is -30v for the 2N4416 and -35v for the 2N4416A. I'm not sure how or if that will effect the rest of the circuit.)

Apologies in advance for committing any of the common newbie mistakes. I've undoubtedly got several unknown-unknowns related to the topic of DIY circuits, so if there's something that could be changed to improve readability or if there's just something that looks odd, feel free to let me know and I'll do my best to fix it!

Thanks!

I'm currently attempting to build a microphone in the same style as [Scott Helmke's "Alice"] mic. Following the parts list and schematic that they've posted to their website.

Given that this is the first electronics DIY project I'm attempting (the wisdom of using this as a first project is yet to be seen.) I'd appreciate anyone looking over how I've translated from the schematic to a stripboard to make sure I haven't made any silly mistakes. (And of course any applicable advice is welcome as well.)

The schematic I worked from (from Scott Helmke's website)

And how I laid the above out in DIYLC

(If it makes a meaningful difference, Mouser was out of specifically the 2N4416 JFETs at the time, so the one I actually have on hand is the 2N4416A variant. Here's a [Link] to the datasheet from Mouser, the difference I'm seeing is the breakdown voltage is -30v for the 2N4416 and -35v for the 2N4416A. I'm not sure how or if that will effect the rest of the circuit.)

Apologies in advance for committing any of the common newbie mistakes. I've undoubtedly got several unknown-unknowns related to the topic of DIY circuits, so if there's something that could be changed to improve readability or if there's just something that looks odd, feel free to let me know and I'll do my best to fix it!

Thanks!