Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

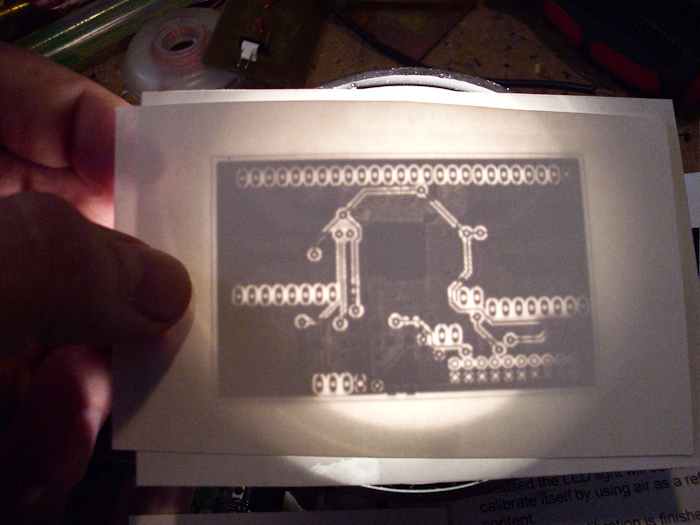

Hi,I wanted to try double sided PCB using toner transfer method. I printed out the top and bottom copper. My question is how to align the printed top and bottom on the PCB sides so that via holes and others are aligned? any tricks and tips?

perfect, great details so useful for beginnersHave a look at Mr Carlson's Lab:

JimB

have a look at my project here:I wanted to try double sided PCB using toner transfer method. I printed out the top and bottom copper. My question is how to align the printed top and bottom on the PCB sides so that via holes and others are aligned? any tricks and tips?