Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hi Vivian,

As John has stated, the PCB multiplexed. It is simple to connect a microcontroller to. Have you decided what you want to do with the value once you have read it from the caliper?

Doug.

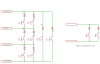

The pattern suggests the following:

PEO-1 is the multiplexed output for the 8 ranges to four wires. Using charlieplexing, 4 wires could read 12 positions ((positions = n(n-1)). I suspect it is charlieplexed.

PBO-1 has the eight wires that read the fine divisions withing each range.

Although that pattern seems likely, I would do some testing with an ohmmeter to confirm it. Set the meter to diode test, if it has that function.

John

I mean the number that the microcontroller derives after reading the position of the calliper. The number that relates to the position of the calliper.I not very understand what you mean by the value get from the caliper.

I mean the number that the microcontroller derives after reading the position of the calliper. The number that relates to the position of the calliper.