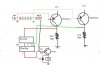

below is overall of my project..

i'm using solar panel to charge up my car battery and use the car battery to power my system

As a example

when the car battery is without loaded, LED1 will light on to show the voltage level of the battery, when i connected to my system, the car battery voltage will drop and LED2 will light on, when i shutoff my system then the LED1 will turn on again

my planing is when the car battery voltage is going low same as LED3 and it will automatically switch off my system, right now i'm using single relay switch (SRD-9VDC-SL-C) in this application, but when it reach LED3, it does'nt switch off my system, because when it reach to LED3 the voltage of the system will off and the voltage of car battery will increase, when the voltage is increase, then my system will on, after my system is on, voltage will drop to LED3 and it will shutoff again, so my system will on off on off and LED4,5,6,7 will blind

anyone know how to solve this problem?

i'm using solar panel to charge up my car battery and use the car battery to power my system

As a example

when the car battery is without loaded, LED1 will light on to show the voltage level of the battery, when i connected to my system, the car battery voltage will drop and LED2 will light on, when i shutoff my system then the LED1 will turn on again

my planing is when the car battery voltage is going low same as LED3 and it will automatically switch off my system, right now i'm using single relay switch (SRD-9VDC-SL-C) in this application, but when it reach LED3, it does'nt switch off my system, because when it reach to LED3 the voltage of the system will off and the voltage of car battery will increase, when the voltage is increase, then my system will on, after my system is on, voltage will drop to LED3 and it will shutoff again, so my system will on off on off and LED4,5,6,7 will blind

anyone know how to solve this problem?