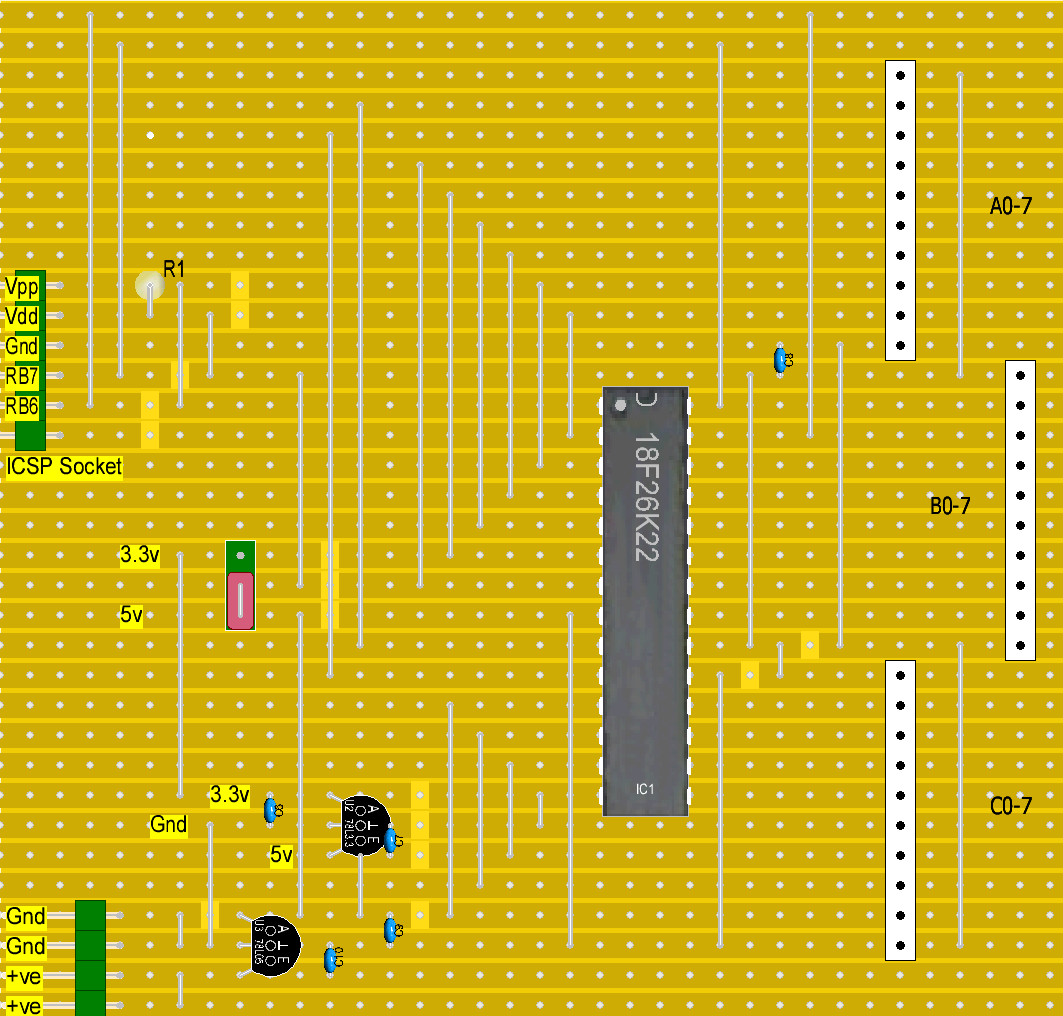

I thought I'd post this, as others might find it useful?. As we've been discussing LCD/TFT usage with PIC's in the Oshonsoft Forum, and the 18F series seemed to be popular, I've ordered a couple of 18F26K22's (chosen for their 28 pin S-DIP package and large memory), so have designed a layout using my standard tutorial board system with ten pin molex connectors. As I'm likely to be playing with 3.3V displays, I've added both 5V and 3.3V regulators, with a link to choose which voltage you want - which saves messing around with level shifters to the display.

Anyway, I've got the board built, plus a connection board for the display (ILI9341), and I'm just waiting for the chips to turn up - I'm 'hoping' they will arrive today, as they were sent via UPS this morning. Basically I'm typing this while keeping on IP camera, that I've stuck in the front bedroom window, so I can see if a van arrives

Anyway, I've got the board built, plus a connection board for the display (ILI9341), and I'm just waiting for the chips to turn up - I'm 'hoping' they will arrive today, as they were sent via UPS this morning. Basically I'm typing this while keeping on IP camera, that I've stuck in the front bedroom window, so I can see if a van arrives

Last edited: