Hello,

I am trying to resurrect an old Panasonic Transistor Radio that has an extremely low volume (and possibly other issues that I'm not aware of yet Have replaced all Electrolytic Capacitors but it didn't seem to solve the problem.

Have replaced all Electrolytic Capacitors but it didn't seem to solve the problem.

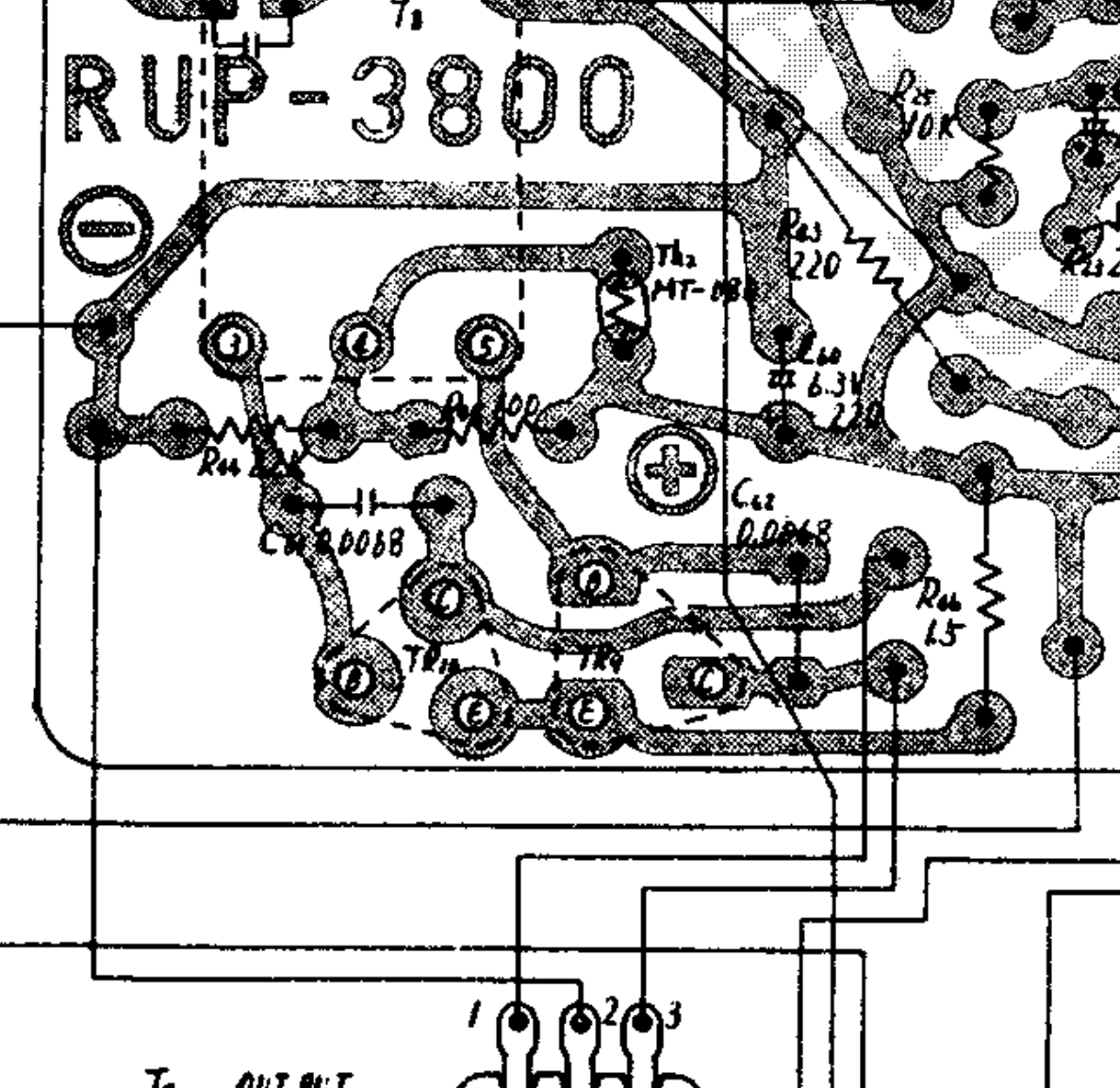

When doing some measurements on the final output stage and comparing it to what the schematic says - the numbers seem quite odd (also I don't really know what I'm doing

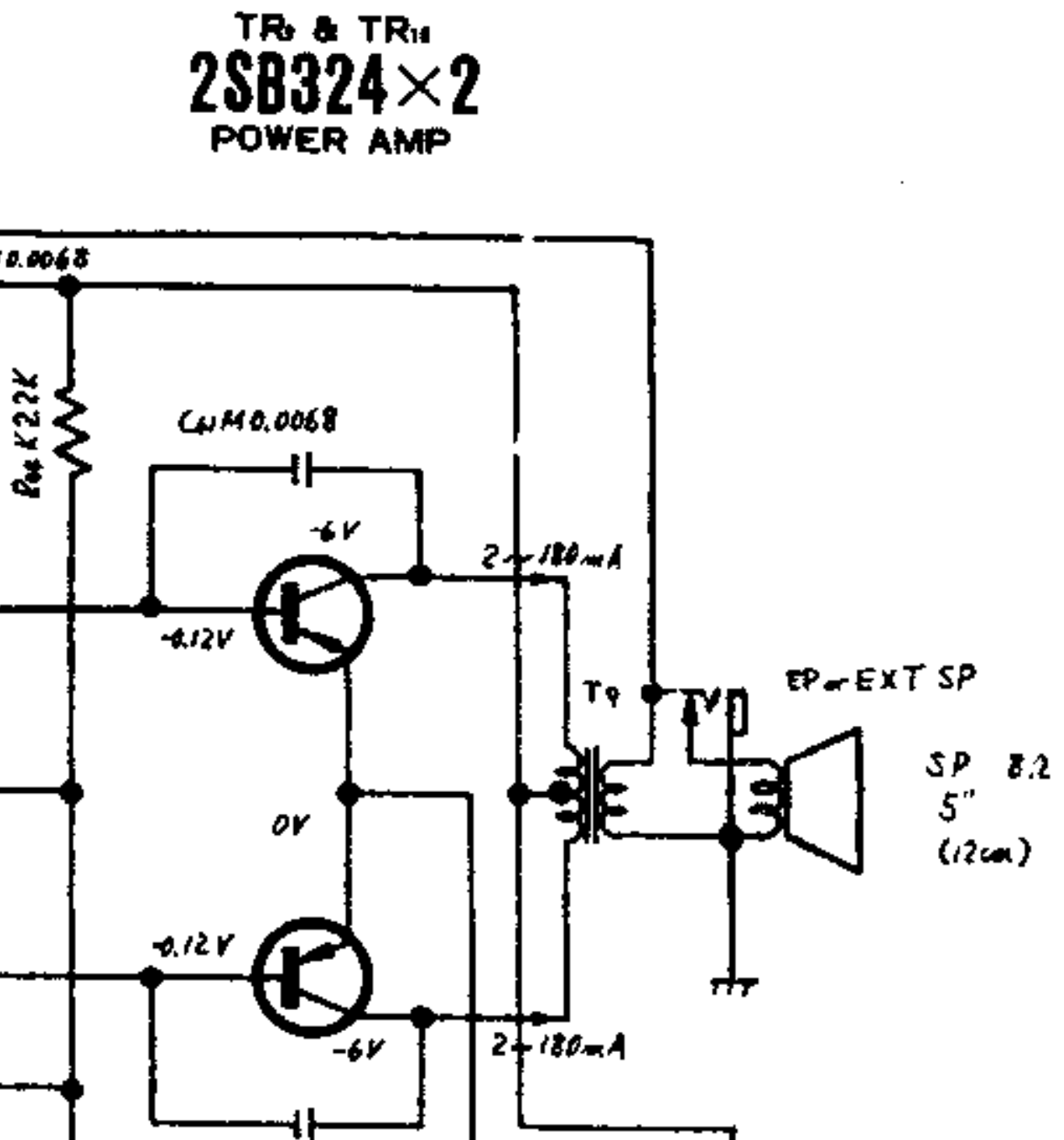

If I read it right, the two 2SB324 power amp transistors should be getting 0.12v at the base, 0v at emitter and 6v at collector.

However then I probe the contacts marked B/C/E on the board for these according to what schematics says, I get:

TR10

B = 5.78v

E = 4 - 4.6v (floats continuously)

C = 0.02v

TR4

B = 4.1 - 4.5v (floats continuously)

E = 4 - 4.6v (the emitter is shared so it's the same as on TR10

C = 0.02v

Would it be right to guess that these two transistors are bust, and if yes what would be an appropriate modern day equivalent, or could the be somewhere else completely?

Thank you

I am trying to resurrect an old Panasonic Transistor Radio that has an extremely low volume (and possibly other issues that I'm not aware of yet

When doing some measurements on the final output stage and comparing it to what the schematic says - the numbers seem quite odd (also I don't really know what I'm doing

If I read it right, the two 2SB324 power amp transistors should be getting 0.12v at the base, 0v at emitter and 6v at collector.

However then I probe the contacts marked B/C/E on the board for these according to what schematics says, I get:

TR10

B = 5.78v

E = 4 - 4.6v (floats continuously)

C = 0.02v

TR4

B = 4.1 - 4.5v (floats continuously)

E = 4 - 4.6v (the emitter is shared so it's the same as on TR10

C = 0.02v

Would it be right to guess that these two transistors are bust, and if yes what would be an appropriate modern day equivalent, or could the be somewhere else completely?

Thank you

)

)