I own a 2006 Corolla, and have been listening to the coverage of Toyota's accelerator recall. I haven't received a recall notice yet, but I expect to. Something about the mechanical fix doesn't seem right to me, and there are folks who have been saying that it could be an Engine Control Module software problem, so I got to thinking about it. The Throttle Position Sensor is a potentiometer built by **broken link removed**

I pulled out the Corolla's wiring diagram to see how the Throttle Position Sensor is wired to the ECM. I was questioning what would happen if one of the wires between the ECM and the Throttle Position Sensor became disconnected? Could that cause the ECM to think that the pedal was all the way to the metal, and cause a "runaway"?

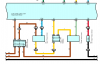

Here is a fragment of a wiring diagram that spans 13 pages. The Throttle Position Sensor is T1, the light blue rectangle in the lower right. The ECM is the big blue mass at the top. What follows is my speculation as to how it functions: If there are any trained Toyota mechanics that can correct my speculation, please chime in...

T1 pin 3 is the wiper of the Throttle Position Sensor pot and it goes to ECM pin VTA. T1 pin 2 is the low side of the pot and goes to ECM pin E2 via the junction block and brown wire. T1 pin 1 is the high side of the pot and goes to ECM pin VC via the junction block and yellow wire.

Interestingly, the pot high side is driven by a pin on the ECM rather than being tied to a source of 12V. Similarly, the pot low side is driven from a pin on the ECM rather than being tied to a ground lug. I'm speculating that this is so the ECM can test for an open Pot or bad connection.

During normal operation, presumably the ECM drives VC high, and drives E2 to ground. That allows the ECM to A/D what comes in on VTA to determine the pedal position. Presumably, during a Power Up test, the ECM can remove power from VC (or switch it to ground) which would cause VTA to go to ground so that the ECM can check half the the connections. By driving Vc high, and turning off E2, that would cause VTA to rise to the max voltage, so the ECM can check the other connections and the pot integrity.

I know that this type of scan is done when the key is first turned on, but is it done continuously during driving?

If the self-test is periodic while driving, say once a second, then if the connection between T1 pin 2 and ECM pin E2 became disconnected, the ECM would know that the High on VTA is caused by a broken wire, not because the pedal was floored. If the self-test only happens once during key-on, then the ECM could think that a broken wire means go fast???

So, does anybody know how often the self-test is done????

I pulled out the Corolla's wiring diagram to see how the Throttle Position Sensor is wired to the ECM. I was questioning what would happen if one of the wires between the ECM and the Throttle Position Sensor became disconnected? Could that cause the ECM to think that the pedal was all the way to the metal, and cause a "runaway"?

Here is a fragment of a wiring diagram that spans 13 pages. The Throttle Position Sensor is T1, the light blue rectangle in the lower right. The ECM is the big blue mass at the top. What follows is my speculation as to how it functions: If there are any trained Toyota mechanics that can correct my speculation, please chime in...

T1 pin 3 is the wiper of the Throttle Position Sensor pot and it goes to ECM pin VTA. T1 pin 2 is the low side of the pot and goes to ECM pin E2 via the junction block and brown wire. T1 pin 1 is the high side of the pot and goes to ECM pin VC via the junction block and yellow wire.

Interestingly, the pot high side is driven by a pin on the ECM rather than being tied to a source of 12V. Similarly, the pot low side is driven from a pin on the ECM rather than being tied to a ground lug. I'm speculating that this is so the ECM can test for an open Pot or bad connection.

During normal operation, presumably the ECM drives VC high, and drives E2 to ground. That allows the ECM to A/D what comes in on VTA to determine the pedal position. Presumably, during a Power Up test, the ECM can remove power from VC (or switch it to ground) which would cause VTA to go to ground so that the ECM can check half the the connections. By driving Vc high, and turning off E2, that would cause VTA to rise to the max voltage, so the ECM can check the other connections and the pot integrity.

I know that this type of scan is done when the key is first turned on, but is it done continuously during driving?

If the self-test is periodic while driving, say once a second, then if the connection between T1 pin 2 and ECM pin E2 became disconnected, the ECM would know that the High on VTA is caused by a broken wire, not because the pedal was floored. If the self-test only happens once during key-on, then the ECM could think that a broken wire means go fast???

So, does anybody know how often the self-test is done????

Attachments

Last edited: