re: your shop Mill PCB problem

WOW -

Had no idea you were in England of all places. I guess this site here takes posts from all the world as it were!

I couldn't help but add in some of my expert repair advice here, as I've repaired a few treadmills (TM's) in my time, and most were a bit more complicated then the SIMPLE PCB motor control you are showing in your post. I guess at roughly $1100 for that Mill you have there - the mfr in Austria wouldn't just swap out the boards huh? Guess not! Either that or it's a cheaper model with a only a few basic bells and whistles - as by the small footprint PCB design and all?

First of all - some basic sound soldering/desoldering advice is needed here.

NEVER USE copper desoldering braid if you can help it! It only helps to ruin the PCB copper runs when too much heat is constantly applied to the solder point to be worked on. Buy an inexpensive but quality type plunger desoldering tool if you can. They are under $10 and well worth the money! Practice on some bad throwaway boards first to become a desoldering Pro first, and then apply it to the good boards! You will appreciate the ease at which the solder now comes off the board, but never damages fragile PCB's. That or if you must use that copper braid then use a liquid acid flux first - on the spot to be desoldered - such as a #30 by Superior Flux & Mfg Co. Solder will now flow off the spot much quicker, and with less damaging pressure effects from the soldering iron TIP force being applied, and will also help reduce the overall heat damaging effects greatly.

Same goes for a good soldering station as well. My station of choice was/is a Weller model TC-202 (WTCPN series) base unit using a TC-201 pencil assy with Zero Tip Voltage Isolation and automatic temp controlled tip system that uses preset soldering tips according to their size (wattage or heat delivered) and use.

Even though the unit's rated output wattage might be stated at 60 watts that doesn't mean that is what is at the TIP point in so far as for heat wattage delivered. Bigger TIPS produce more wattage in the form of point area and heat. Smaller TIPS just the opposite. If I want more Tip Heat for doing bigger desoldering areas where I have to stay in contact a bit longer then I use a bigger Tip. Where delicate work is involved I use a smaller Tip.

I also don't need the fancy digital displays and extra bells and whistles with more expensive units, as I consider myself a Pro when it comes to component level repair! I learned from the BEST starting out in my Electronics Degreed field and then some!

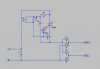

As for your posted PCB there - sure is a small control board in that shop Mill.

Most jogging/running TM's that I've worked on have 2 bigger PCB's minimum in the belt drive "motor compartment". One is the CPU Logic Brd, and the other usually being the Drive Brd. Of course you don't have a TM, so that goes without reason. Your shop Mill there looks to be a fairly simple piece of work equipment in this case.

In checking the PCB components whether they are diodes, resistors, or just basic diode junction transistors ALWAYS USE a good quality DVM to perform those tests (or a cap testing meter), and NOT by using an older analog type multi-meter - such as what I believe you are using unless I'm guessing wrong here? I just don't trust the older analog meters anymore - those that I too grew up with when I first started out eons ago now!

In troubleshooting (T/S) your (any) PCB there - always desolder only 1 lead from any axial 2-lead passive component (unless it's a multi-pin/lead passive device package then remove it entirely). Where the component IS a typical 3-pin active device transistor, SCR, TRIAC, or say (MOS)FET in nature - then definitely desolder the related part totally - even if it's heatsinked to the PCB, as otherwise you will never DVM check it out properly. Unless you definitely KNOW that the latter is true then there's no need to remove it (ie: burnt or cracked casing, etc).

I've had to do the latter with higher priced TM's even though the related Power Resistors on the PWM motor drive boards were at fault to begin with. Just because a high wattage SURGE resistor "looks good" on the outside doesn’t mean it "IS GOOD" inside. I've seen them go out of spec by as much as 50-60% of rated value and tolerance, and even partially OPEN UP when superheated - or act as an OPEN in the SURGE or feedback circuit - thus sending the control board into shutdown!!

Rarely will a 3/4 turn or single turn TRIM POT go bad unless it's a cheaply made variety to start with. I've seen the ones like you have there - on your PCB - have wiper intermittents - as from contact age, but it's rare. Always look for the obvious first!

Tapping the side of the POT slightly while measuring it should show no signs of value wander! If it jumps then its SHOT - replace it. Try and measure its "set point" out of circuit first, and replace it with a 10-turn POT instead - so a more accurate setting can be made after the R&R.

Which makes me wonder about what you said in your original post about the shop Mill making a "bang" and then it just stopped working?? That sounds more like a startup CAP blowing out - in regards to the "bang" you mentioned, unless that was indeed a purely mechanical bang you heard?

Are you sure the motor doesn't have a "soft start" CAP feature added to that drive motor mounted somewhere? Some shop routers use a "solid state" PCB soft start feature, and use a specially wound "Y" motor as well - one with a special "Y" startup winding added so that it retards a fast ramp up in speed current, but their PCB design usually has a weak IC controller chip on it - that when it fails nothing works at all. That chip being all but "proprietary" in nature is all but harder then hell to find should it (the IC chip) ever go bad - as I once found out fixing a 3hp model. I wound up just bypassing (gutting out) the controller board altogether, and just made it a single speed router. With an added $12-13 aftermarket external speed controller I bought from Harbor Freight Tools at 1/2 price on sale it worked just fine as a permanently mounted - fully speed controlled - bench router!

Anyway -

In your case - your PCB there doesn't show any outward signs of component failure at all, but to have all the bridge diodes go bad (as you say) tells me there is more going on there then just the PCB as it were. Btw - that TRIAC is just epoxyed in place so as to help prevent micro-arching should the soldered leads come loose from any excessive vibration, as I'm guessing there is when running under load. Do you have a lot of hours on the Mill? Have you also checked the DC motor brushes? Maybe the DC motor brushes are near their end life if there are high hours on the Mill? Have you ever checked them out as well?

As far as for finding electronic component parts online - I would stay away from Mouser and Digi-Key as they are a big rip off to start with - as related to their ridiculous parts price markups and all (making their real profit killing on the shipment part as you too have somewhat stated). Newark isn't too bad I would guess - although I have never had to order any electronic parts online, and then have to deal with the shipping part as well. I have tons of electronic parts outlets all around me where I live! I would maybe try NTE parts replacement if they can cross-reference that original part you have there to start with. Otherwise their direct NTE replacement part for that Q6004L4 is an NTE5645.

Hope this helps out. Let us all know OK?

Frank