Hi David,

There are many commercial units available made exactly for this job.

Most of them involve the vertical movement of the air-to-water

interface at the surface of the water in the tank to register level.

This range includes those units which rely on things that float,

and units which rely on things that bounce echoes,

and units which rely on conduction sensors that make contact with

the water itself.

All of these types which involve surface interaction have their own

problems ranging from pivots that sieze, floats that leak, cobwebs

that echo, damp that attacks electrics, corrosion that can wreck

electronics, insects that set up home in electrical units. Problems

too numerous to list, most of which can be overcome by frequent

maintainence.

The most reliable arrangement that i have met for this job where an

underground tank is involved, is the simple bubbler pressure sensor.

With this type of unit all the electrics and sensing gear is above

ground, and can be easily accessible if necessary.

The piece that goes into the water is just a length of tubing with an

open end. Probably tied to a stone to ensure it stays at the bottom.

Tubing probably plastic so that it wont corrode. Weight probably a

stone or a brick so that it wont corrode. Tied with maybe itself or

plastic string so that it wont corrode.

This is the most reliable and maintainence free arrangement i have

ever seen on this type of job. Just keep the air flow pretty low,

just enough for about a bubble per second roughly, as i have known

one which was set too high had a build up of grime and dust due to

the air flow. It did not stop it working, but it got a bit messy.

after cleaning and adjusting the air flow down to a sensible low flow

it was fine and stayed clean. I think faster moving air seems to stir

up dust and carry it about.

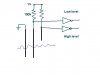

The associated electrics for this type of arrangement is very simple

generally a diaphragm is used to operate switches at the pressures

corresponding to the 'Hi' and the 'Lo' levels.

If an 'all-electronic' arrangement is wanted, there are pressure units

that can be used with electronics instead of diaphragms.

Fish-tank type pumps are cheap and very reliable, and count typical

running time in months or years.

Best of luck with your project, John