SentinelAeon

Member

Hello,

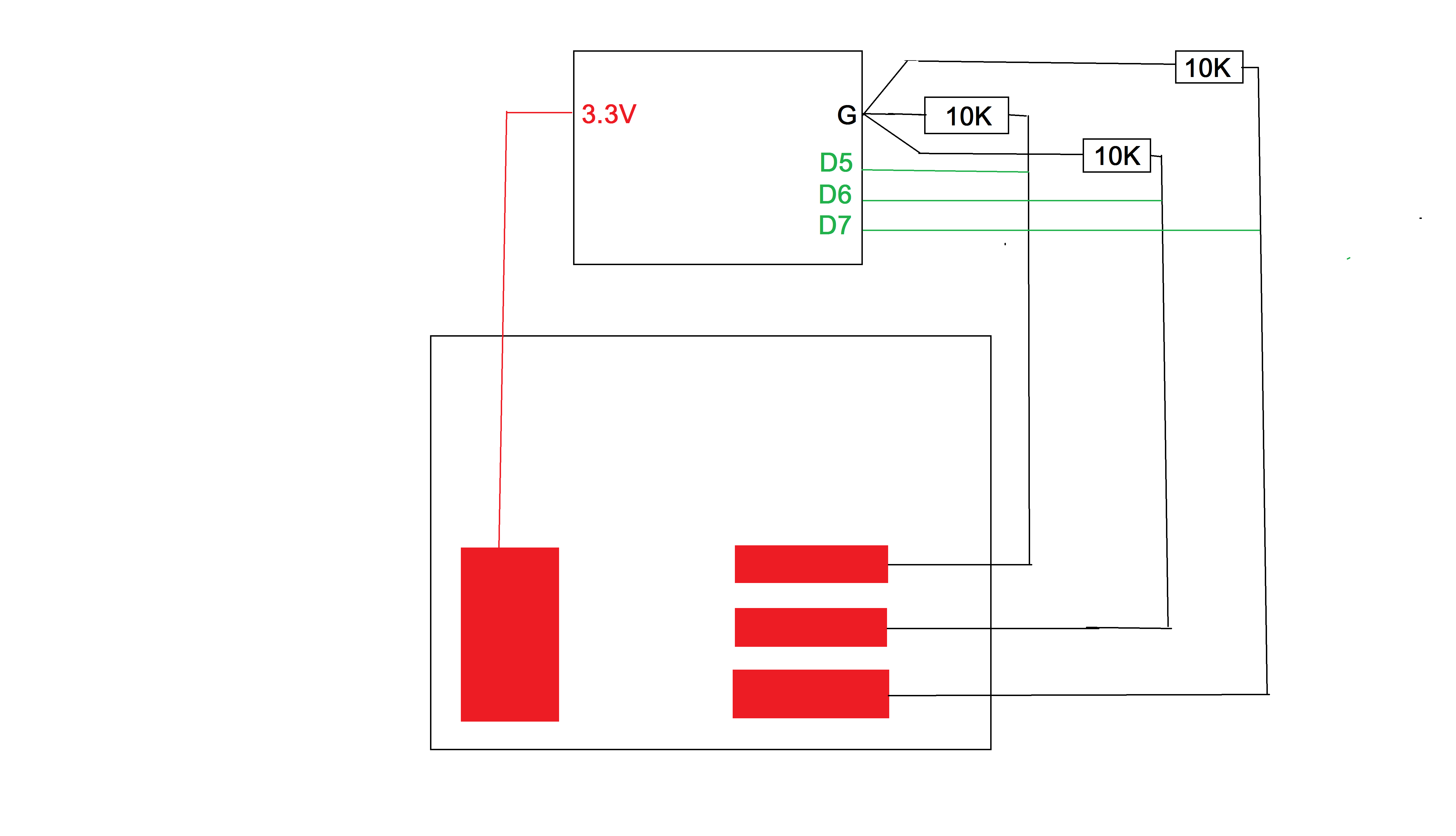

I made a simple DIY water level sensor. I set D5, D6 and D7 to INPUT. I connected all those pins to ground by 10K resistor to pull them down and connected them to metal plates that will detect the water level (red squares on the right, 3 of them). I connected a big metal plate to 3.3V pin (big red square on left). So when water level is high enough, the D5, D6 and D7 pins will detect "high" on them. I just tested it and it works the way i wanted it to work. If i short the plates on left and right with a wire, i detect a 0.3 mA gcurrent. Obviously with water it would be less. So my questions are two:

1) Is this setup ok in a way that it won't harm my ESP8266 board.

2) Is electrolysis going to be a problem at such low current ? The metal plates aren't copper but the wire is. It is mostly covered with solder but about 1mm of it is exposed. Should i cover it all with solder and cover with epoxy resin to protect it completely ?

I made a simple DIY water level sensor. I set D5, D6 and D7 to INPUT. I connected all those pins to ground by 10K resistor to pull them down and connected them to metal plates that will detect the water level (red squares on the right, 3 of them). I connected a big metal plate to 3.3V pin (big red square on left). So when water level is high enough, the D5, D6 and D7 pins will detect "high" on them. I just tested it and it works the way i wanted it to work. If i short the plates on left and right with a wire, i detect a 0.3 mA gcurrent. Obviously with water it would be less. So my questions are two:

1) Is this setup ok in a way that it won't harm my ESP8266 board.

2) Is electrolysis going to be a problem at such low current ? The metal plates aren't copper but the wire is. It is mostly covered with solder but about 1mm of it is exposed. Should i cover it all with solder and cover with epoxy resin to protect it completely ?