Bear with me on this, it's a long post but I believe a very simple question for the pros in this forum..=)

im reading values from a SHARP GP2Y0A21YK Distance Sensor and inputting the sensor output values to a 877A for ADC conversion.

I have pretty much implemented the ADC and output the digitized values to an array of 8 LEDs representing the MSB to the LSB of the result.

However, due to the imperfection of output voltage values from sensors, the digitized ADC result on the LEDs tend to flicker at certain bits while there are dominant bits which clearly stay lit. (thus indicating a somewhat vague result with superimposed noise)

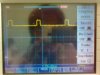

I scoped the sensor output on an oscilloscope and found out that the Vavg is stable but there is noise superimposed on it at about 300mV on average...Hence, I inserted a smoothing capacitor on the signal lines and indeed the digitized result became more stable with less LED flickering. However, I would really love to get a stable voltage with no flickering of the LED's whatsoever.

Hence, there are 2 methods i propose to undertake to increase the stability of the digitized results and would really love advice on it...

1) Reducing the resolution of the ADC

Im currently doing a 10 bit resolution ADC.If i further decrease the resolution, the smaller noise signals will then not affect the ADC process.

Is there any way I can reduce the resolution to 8 bits? The 877A uses a 10 bit resolution into 2 registers ADRESH and ADRESL. Is resolution decreasing possible?

2) Adding another stage of signal conditioning after the capacitor.

Any suggestions on a good signal conditioning circuit for the aforementioned purpose?

Out of the 2 which would be more advisable?

Thank YoU!=)

im reading values from a SHARP GP2Y0A21YK Distance Sensor and inputting the sensor output values to a 877A for ADC conversion.

I have pretty much implemented the ADC and output the digitized values to an array of 8 LEDs representing the MSB to the LSB of the result.

However, due to the imperfection of output voltage values from sensors, the digitized ADC result on the LEDs tend to flicker at certain bits while there are dominant bits which clearly stay lit. (thus indicating a somewhat vague result with superimposed noise)

I scoped the sensor output on an oscilloscope and found out that the Vavg is stable but there is noise superimposed on it at about 300mV on average...Hence, I inserted a smoothing capacitor on the signal lines and indeed the digitized result became more stable with less LED flickering. However, I would really love to get a stable voltage with no flickering of the LED's whatsoever.

Hence, there are 2 methods i propose to undertake to increase the stability of the digitized results and would really love advice on it...

1) Reducing the resolution of the ADC

Im currently doing a 10 bit resolution ADC.If i further decrease the resolution, the smaller noise signals will then not affect the ADC process.

Is there any way I can reduce the resolution to 8 bits? The 877A uses a 10 bit resolution into 2 registers ADRESH and ADRESL. Is resolution decreasing possible?

2) Adding another stage of signal conditioning after the capacitor.

Any suggestions on a good signal conditioning circuit for the aforementioned purpose?

Out of the 2 which would be more advisable?

Thank YoU!=)