Neil_Measurement

New Member

Hello,

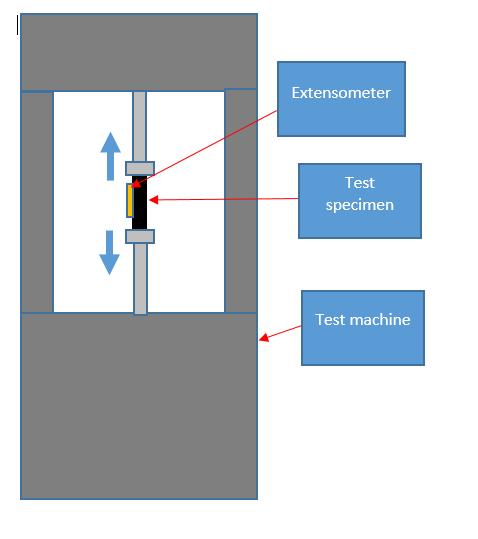

I am working for a company that produces video based measurement systems. One of the key measurements in materials testing is the measurement of strain. Strain is the amount of extension of a material compared to its original length, normally this extension is induced by a force applied by a test machine.

This is normally measured using an extensometer:

There is a port in the Universal Test Machine (UTM) that allows the extensometer to be plugged in. Through this port a reading of extension is given as a signal.

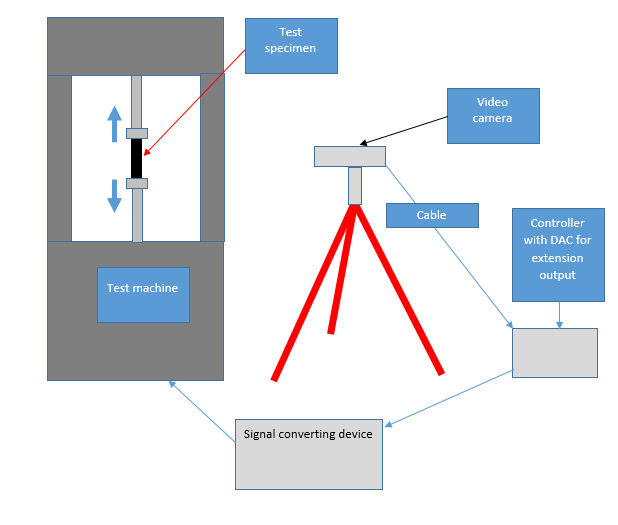

I however would like to use a video measurement system to generate the extension signals, however I need a device to convert from the signals given by out DAC to the signals required given out by an extensometer (so I can plug them into the UTM).

There will be a single extension output from our DAC:

· +/- 10 volts

· + and – signals (differential)

An Extensometer however is more complicated. It normally consists of a Wheatstone bridge, where one or more of the 4 resistors is/are strain gauge(s):

The extensometer port therefore will have four connections:

· +/- excitation

· +/- signal

One crucial element is that the signal is proportional to the excitation voltage, because the excitation voltage can vary from 3 to 12 volts.

Instead of strain being applied to the device, it will be a voltage signal being applied. Therefore it also has to be proportional to the strain signal. Therefore what I will need is a way to multiply two signals together with very high accuracy.

So far I have gathered a few ideas from people:

· Convert everything to a digital signal. I could then use a microcontroller to do the multiplication.

· Use digital resistors in the same bridge layout.

· Use FETs in the region where they act like voltage controlled resistors.

· Use an off-the-shelf multiplier IC.

I haven’t great experience with any of these methods, so I would like to know your thoughts on these ideas and whether I may have missed any other ideas.

Let me know if this doesn't make sense.

Thanks,

Neil

I am working for a company that produces video based measurement systems. One of the key measurements in materials testing is the measurement of strain. Strain is the amount of extension of a material compared to its original length, normally this extension is induced by a force applied by a test machine.

This is normally measured using an extensometer:

There is a port in the Universal Test Machine (UTM) that allows the extensometer to be plugged in. Through this port a reading of extension is given as a signal.

I however would like to use a video measurement system to generate the extension signals, however I need a device to convert from the signals given by out DAC to the signals required given out by an extensometer (so I can plug them into the UTM).

There will be a single extension output from our DAC:

· +/- 10 volts

· + and – signals (differential)

An Extensometer however is more complicated. It normally consists of a Wheatstone bridge, where one or more of the 4 resistors is/are strain gauge(s):

The extensometer port therefore will have four connections:

· +/- excitation

· +/- signal

One crucial element is that the signal is proportional to the excitation voltage, because the excitation voltage can vary from 3 to 12 volts.

Instead of strain being applied to the device, it will be a voltage signal being applied. Therefore it also has to be proportional to the strain signal. Therefore what I will need is a way to multiply two signals together with very high accuracy.

So far I have gathered a few ideas from people:

· Convert everything to a digital signal. I could then use a microcontroller to do the multiplication.

· Use digital resistors in the same bridge layout.

· Use FETs in the region where they act like voltage controlled resistors.

· Use an off-the-shelf multiplier IC.

I haven’t great experience with any of these methods, so I would like to know your thoughts on these ideas and whether I may have missed any other ideas.

Let me know if this doesn't make sense.

Thanks,

Neil