I've just fixed, for the second time, a small TV with integrated DVD player. The power supply has three Schottky diodes in parallel as the main rectifier on the low voltage output of the SMPS. The first time I fixed it, I hadn't realised exactly what was wrong with the power supply and I changed the whole board, which cost about £20. It's one of these:- https://i.ebayimg.com/images/g/IS0AAOSwCi5kuYN1/s-l500.jpg

The three diodes are to the left of the transformer. They are the three with the cathodes near the axial inductor and the four electrolytic capacitors on the left of the board.

I later realised what had actually gone wrong was that the middle diode had failed short circuit.

This time, I found that the same diode on the new board had failed. When I swapped it for one of the working ones from the old board, it worked.

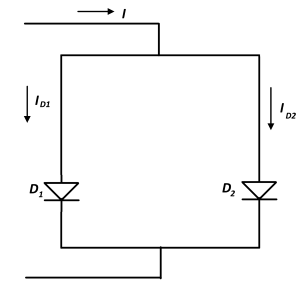

Ok, so there is a marginal design that can have a thermal runaway because Toshiba shouldn't have paralleled Schottky diodes.

The board is designed for various configurations. There is even space for a completely different transformer set at 45°, and its outline can be seen poking out from under the transformer that is actually fitted.

Between the failed diode and the one above it, there is space for a fourth diode in parallel. I've fitted a fourth diode as I had one from the old board.

Is that going to help or make things less reliable?

The three diodes are to the left of the transformer. They are the three with the cathodes near the axial inductor and the four electrolytic capacitors on the left of the board.

I later realised what had actually gone wrong was that the middle diode had failed short circuit.

This time, I found that the same diode on the new board had failed. When I swapped it for one of the working ones from the old board, it worked.

Ok, so there is a marginal design that can have a thermal runaway because Toshiba shouldn't have paralleled Schottky diodes.

The board is designed for various configurations. There is even space for a completely different transformer set at 45°, and its outline can be seen poking out from under the transformer that is actually fitted.

Between the failed diode and the one above it, there is space for a fourth diode in parallel. I've fitted a fourth diode as I had one from the old board.

Is that going to help or make things less reliable?