I have a Dialarc HF-P that I used solely for TIG welding between 1983 and about 2003. It has been in mostly temperature controlled storage since that time, except for the last 4 years. It is in great physical shape.

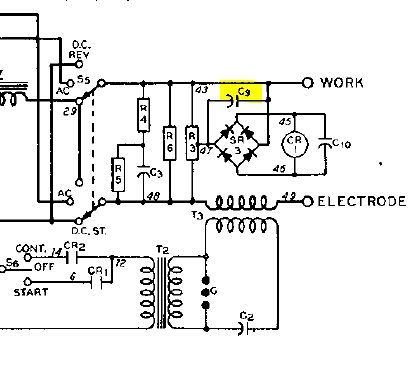

I was worried about capacitors on start up. Most of them are ceramic or mica and are not a concern. There is one electrolytic (22 uF, 50V, axial) shown as C9 here:

1) If it blows, it won't be hard to replace; although, I don't have any with axial leads laying around. Would you be particularly worried about it? C2 is mica and C3 is metal film, 10 uF, 220V.

2) My main question regards a paper oil capacitor (40 uF, 460 VAC) used for power factor correction (not shown). Physically, it looks like new, is quite large, and would probably very expensive today. The welder has not has a lot of use time (<<1000 hours probably). I can accept that the capacitor may go bad with the time. The question is whether paper-oil capacitors should be "reformed" to avoid an early failure or would that effort be meaningless?

John

I was worried about capacitors on start up. Most of them are ceramic or mica and are not a concern. There is one electrolytic (22 uF, 50V, axial) shown as C9 here:

1) If it blows, it won't be hard to replace; although, I don't have any with axial leads laying around. Would you be particularly worried about it? C2 is mica and C3 is metal film, 10 uF, 220V.

2) My main question regards a paper oil capacitor (40 uF, 460 VAC) used for power factor correction (not shown). Physically, it looks like new, is quite large, and would probably very expensive today. The welder has not has a lot of use time (<<1000 hours probably). I can accept that the capacitor may go bad with the time. The question is whether paper-oil capacitors should be "reformed" to avoid an early failure or would that effort be meaningless?

John