Hi,

I want to create a PWM controller for a small DC motor (for academic reasons).

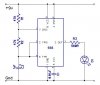

I figured that a 555 timer could create the appropriate pulse.

I simply got the 555 LED flasher (attached) and modified it slightly.

* Instead of the LED, I have the motor.

* R1 is 670Ω and R2 is 300Ω

* C2 is 0.1F

If I understnad it correctly, that should make a pulse frequency of about 15KHz at a ratio of about 1:1

I may have misunderstood it completely though.

Mostly is just makes a squealing noise, although sometimes it does turn.

The motor is just a small 9000RPM DC motor. It's a 6v motor, but I'm running it from a 9v battery (although it's only giving 7.7v). Would that be a problem?

Do I need a higher frequency pulse? Is there more to it than just creating a simple pulse that I would use to flash an LED?

Anyone know where I've gone wrong?

I want to create a PWM controller for a small DC motor (for academic reasons).

I figured that a 555 timer could create the appropriate pulse.

I simply got the 555 LED flasher (attached) and modified it slightly.

* Instead of the LED, I have the motor.

* R1 is 670Ω and R2 is 300Ω

* C2 is 0.1F

If I understnad it correctly, that should make a pulse frequency of about 15KHz at a ratio of about 1:1

I may have misunderstood it completely though.

Mostly is just makes a squealing noise, although sometimes it does turn.

The motor is just a small 9000RPM DC motor. It's a 6v motor, but I'm running it from a 9v battery (although it's only giving 7.7v). Would that be a problem?

Do I need a higher frequency pulse? Is there more to it than just creating a simple pulse that I would use to flash an LED?

Anyone know where I've gone wrong?

Attachments

Last edited: