OwenLinton

New Member

G'day guys!

I'm wondering if anyone has any experience related to or ideas regarding making a small programmable winch?

I'm looking to set up a rig that will lower to a set height when I press a button and return home when I repress it.

My friend suggested a servo motor due to the ability to program the amount of rotation however I haven't been able to find a continuous rotation servo with adequate torque (2.5NM - 5NM).

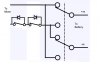

I've also looked at reversible motors however I'm unsure how one would set up a circuit using a limit switch to both lower it and bring it home.

Any help would be much appreciated!

Owen

I'm wondering if anyone has any experience related to or ideas regarding making a small programmable winch?

I'm looking to set up a rig that will lower to a set height when I press a button and return home when I repress it.

My friend suggested a servo motor due to the ability to program the amount of rotation however I haven't been able to find a continuous rotation servo with adequate torque (2.5NM - 5NM).

I've also looked at reversible motors however I'm unsure how one would set up a circuit using a limit switch to both lower it and bring it home.

Any help would be much appreciated!

Owen