Hi,

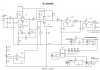

There are many micro circuits for aquarium temperature controllers - one of the more desirable features is the inclusion of a PH probe.

While there are several diy versions on the web, there was always some drawback, either with supply of the part used or its suitablity to aquarium use.

This little unit has been built, tested and used for over 6 months and gives exellent results, using very common, low cost parts.

.

There are many micro circuits for aquarium temperature controllers - one of the more desirable features is the inclusion of a PH probe.

While there are several diy versions on the web, there was always some drawback, either with supply of the part used or its suitablity to aquarium use.

This little unit has been built, tested and used for over 6 months and gives exellent results, using very common, low cost parts.

.