The central locking one my daughter's 2004 Nissan Micra was only working sometimes, so I had a look at it. I don't think that the lock is supposed to be repaired, but they are probably quite expensive, and I would have to wait until Monday or later to get one, so I opened it up.

There are two motors, and the larger one had quite a high resistance, around 20 Ω, and it wasn't working. When I connected a power supply, the current was only 200 mA or so, and it reduced when left connected for a few seconds.

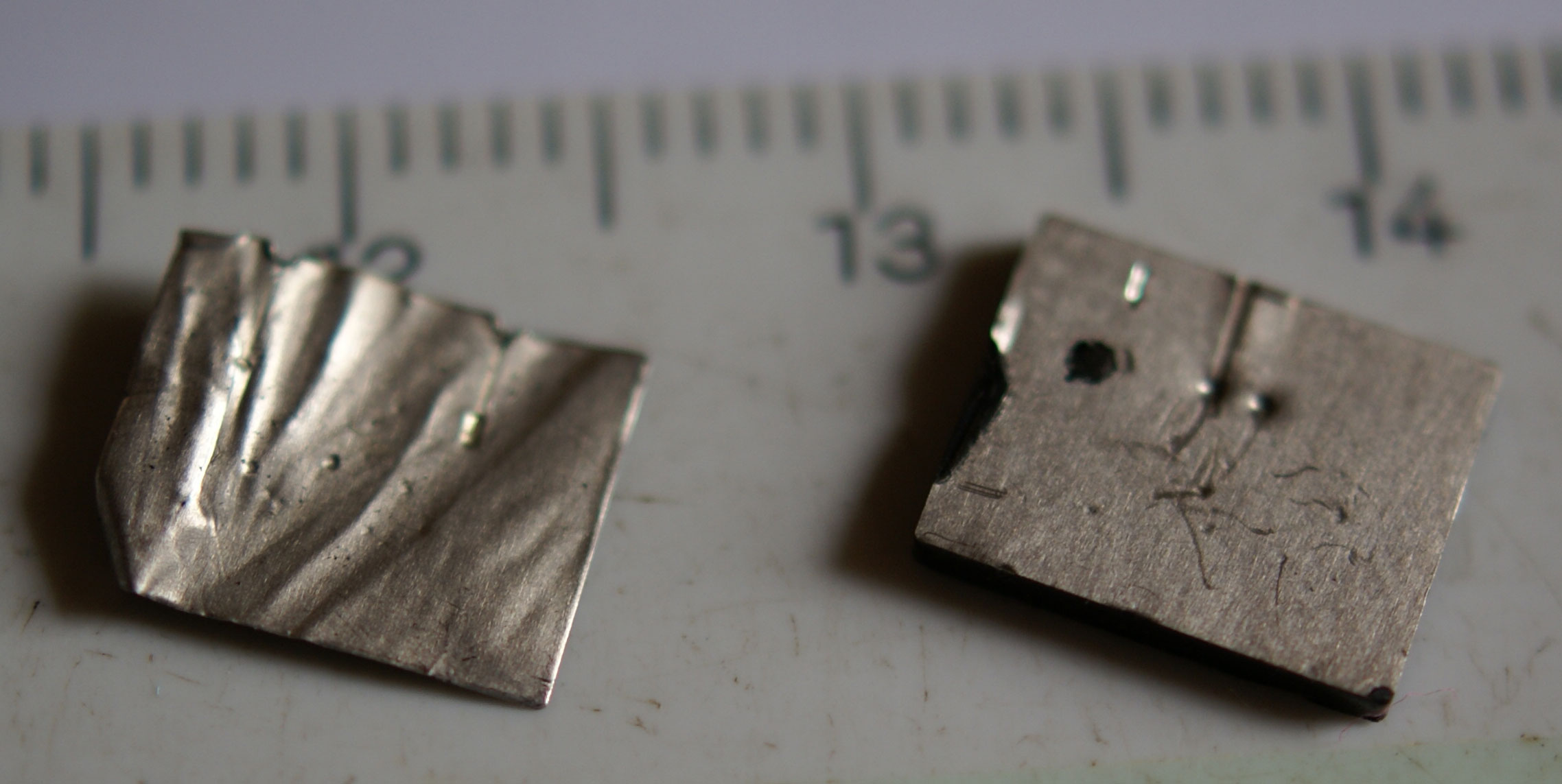

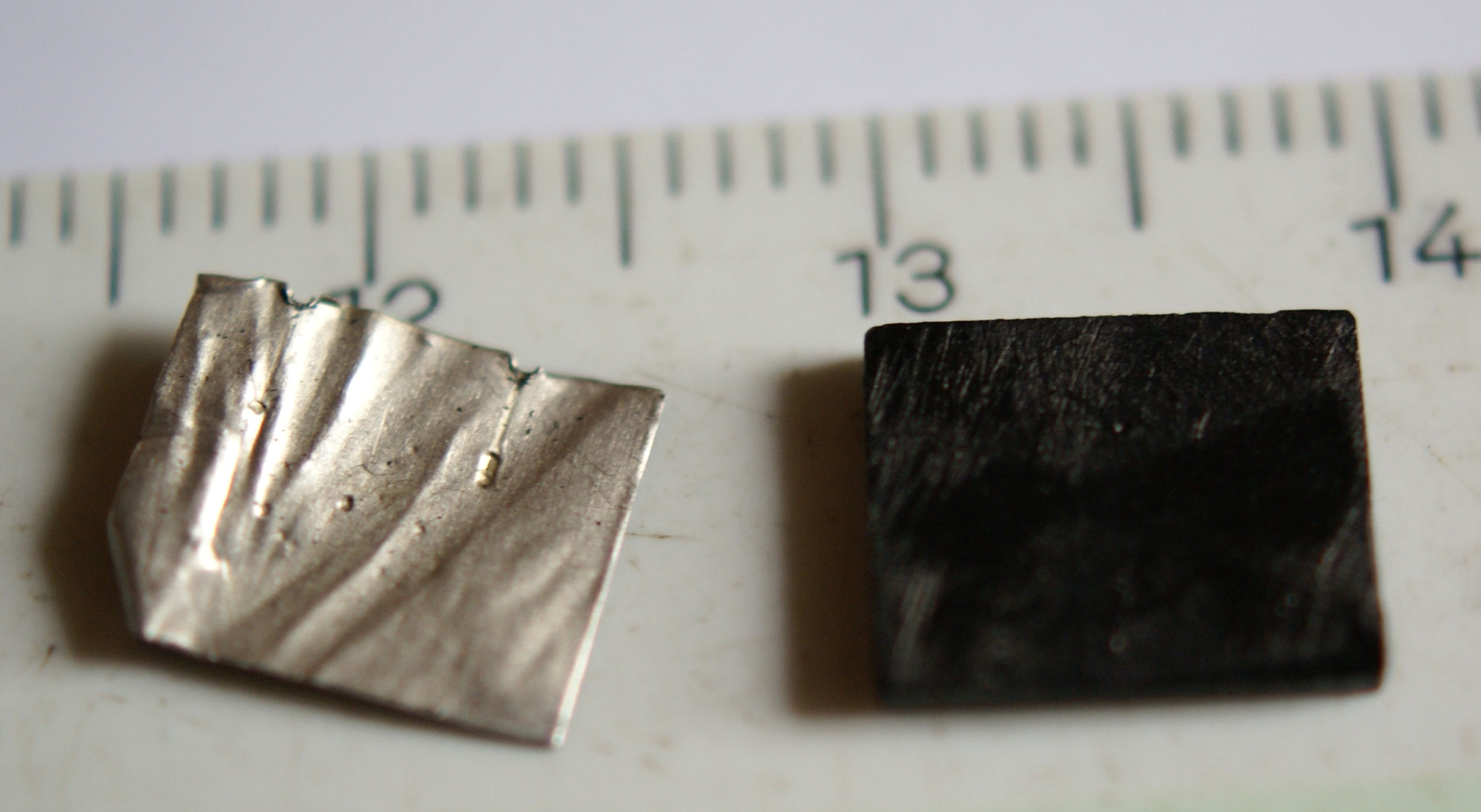

Inside the motor there was a component in series that I can't recognise that provided most of the resistance. The motor itself is around 2 Ω. The component is around 10 x 8 mm, around 2mm thick. It appears to be graphite or similar, with a foil electrode on each 8 x 10 mm face. The electrical connection is made to the foil electrodes.

Has anyone got any idea what this component is?

There are two motors, and the larger one had quite a high resistance, around 20 Ω, and it wasn't working. When I connected a power supply, the current was only 200 mA or so, and it reduced when left connected for a few seconds.

Inside the motor there was a component in series that I can't recognise that provided most of the resistance. The motor itself is around 2 Ω. The component is around 10 x 8 mm, around 2mm thick. It appears to be graphite or similar, with a foil electrode on each 8 x 10 mm face. The electrical connection is made to the foil electrodes.

Has anyone got any idea what this component is?