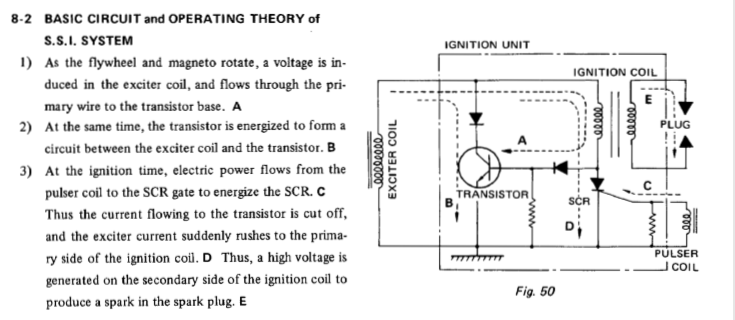

Hello .... I am new to this site but I have read a lot answers from very knowledgeable people who have helped many on this site. I have an older 11 hp small, single piston gasolene engine on a generator with a bad and obsolete SSI ignition (BM5104) . The ignition system consists of an exciter coil, trigger coil and ignition coil. I would like to try and build my own SSi unit that matches my old one. I replaced my exciter coil because I thought the output of 14 to 25 volts ac was too low even though the resistance checks of the exciter coil = .95 ohms and the trigger coil = 69 ohms which are good according to the specs. The ignition coil also is good.Sorry guys but I have already discarded the old SSI module so I don't have it to take apart. I am attaching a diagram of the transistor/SCR crontrolled induction ignition circuit from the engine manual. I really need someone to take a look and give advice on component values if that is possible. I would like to stay with the ac Exciter coil supply system that is already there. Any help is appreciated