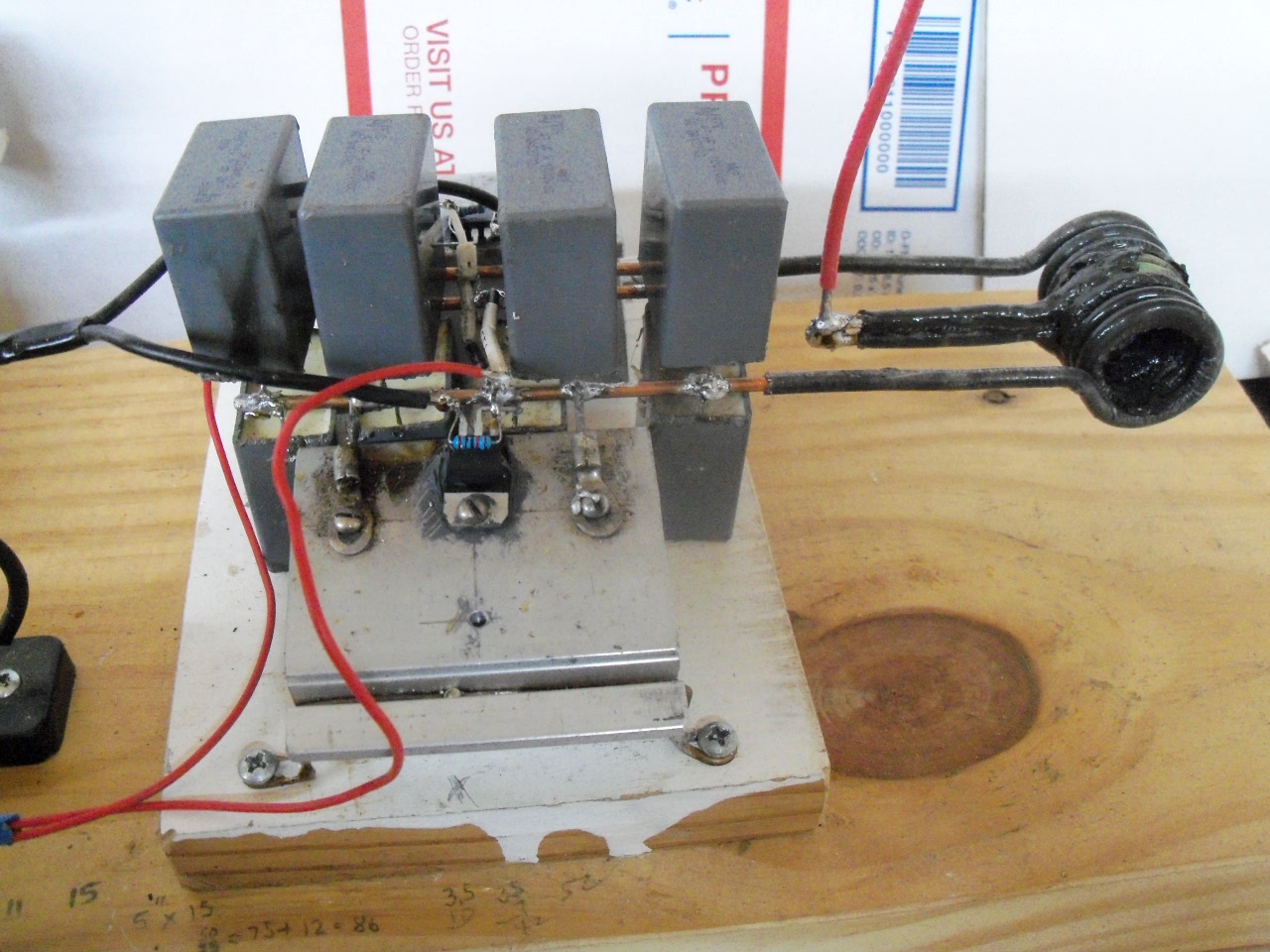

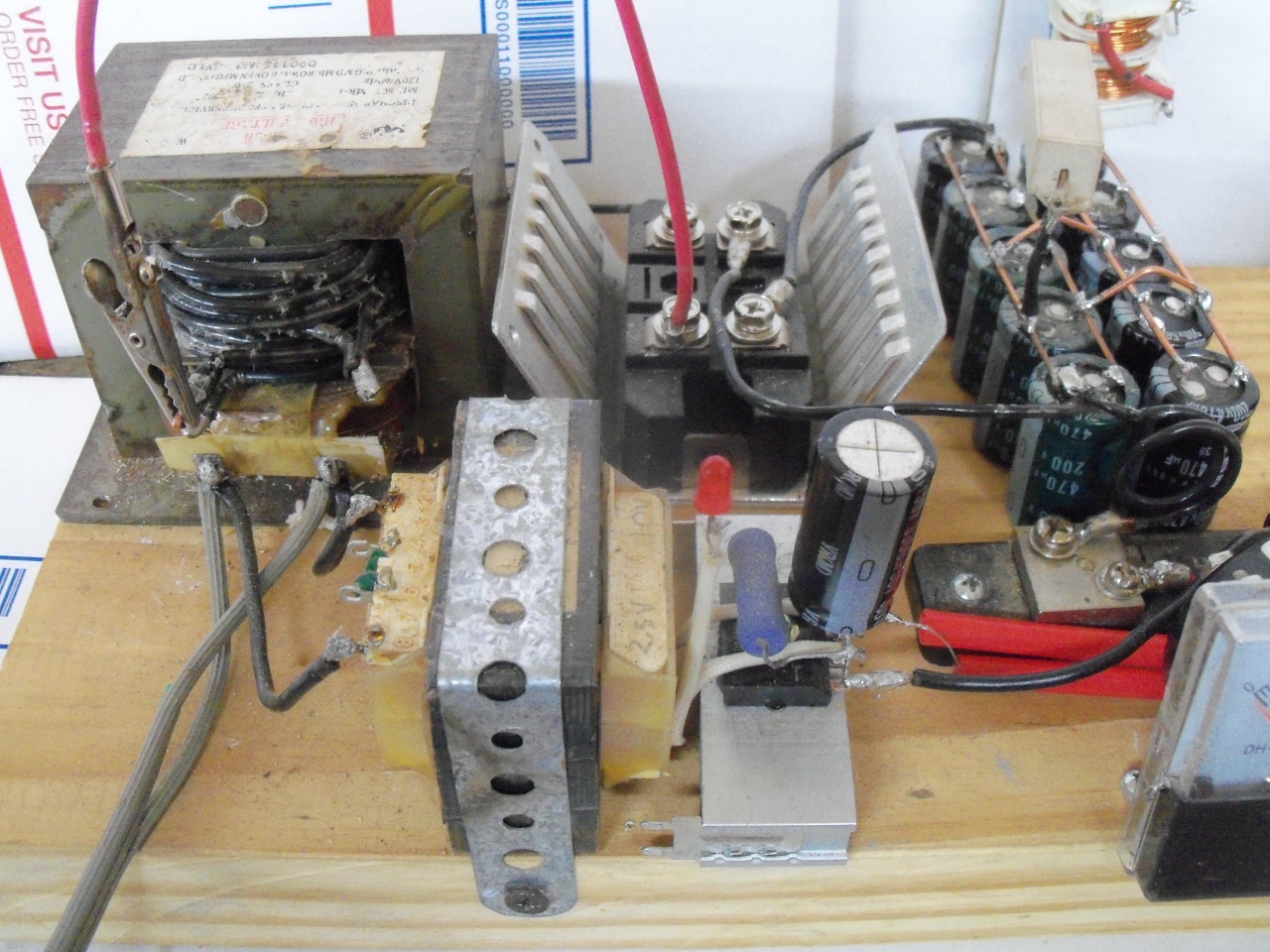

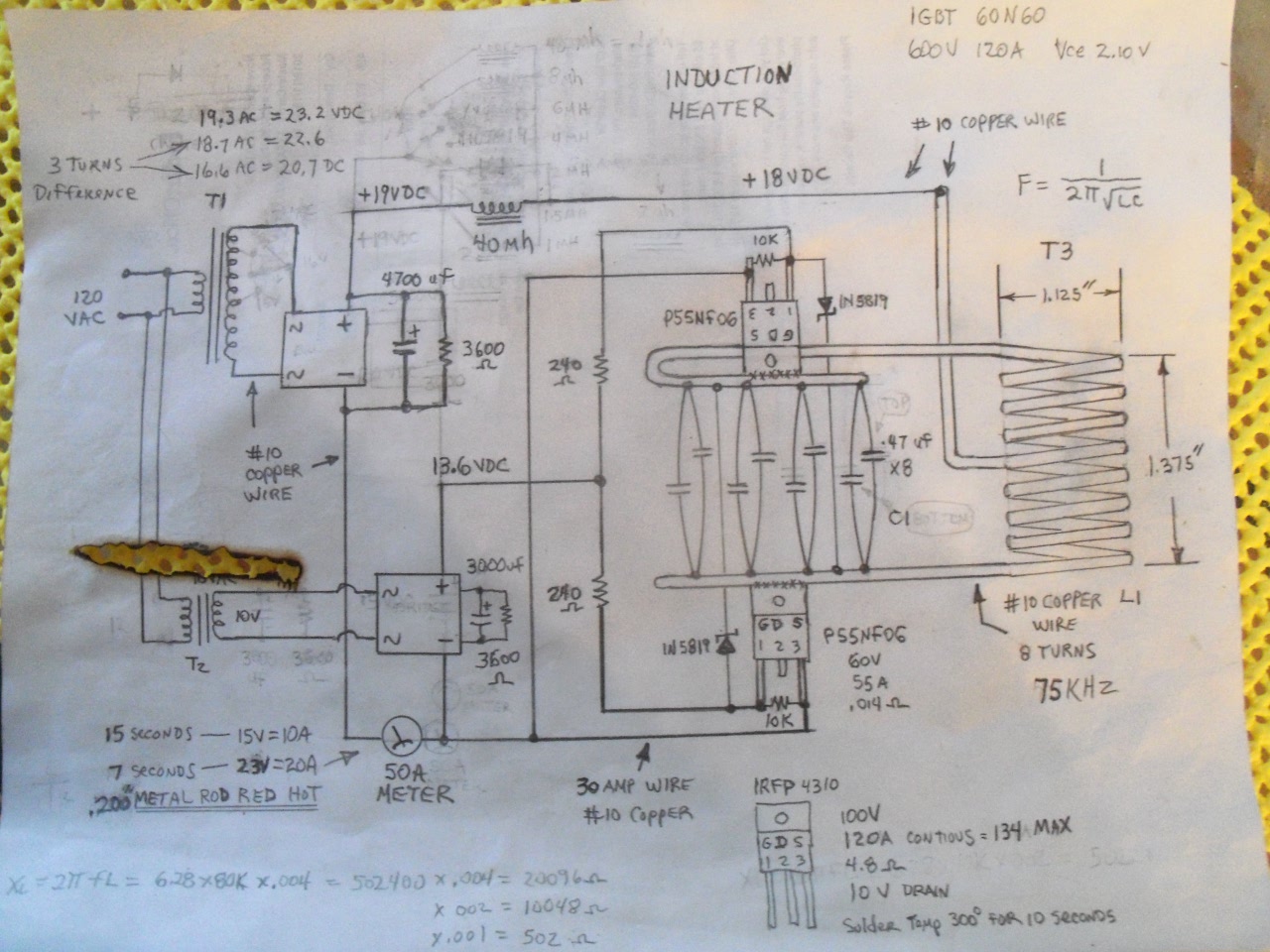

I have been reading everything I can find about Mosfets. I learned my circuit needs a 10K resistor across pin 1 & 3, this makes the mosfet turn completely off on every cycle. Amp meter shows circuit uses 4 amps less with the 10K resistor with no load on work coil. I doubled the power supply cap bank value from 2350uf to 4700uf. I added more taps to the power supply transformer. I tested several power supply induction chokes 40mh works best. Circuit runs at 8a with no load. Insert a 1/4" diameter steel rod into the work coil meter reads 25a then drops to 18a as the rod heats up red hot in 7 seconds. Power supply volts is 23.2 VDC It only takes 45 seconds for #12 solid copper wire work coil to over heat, it needs copper tubing with a water cooling system. Circuit also needs a 12v zener diode across pin 1 & 3. I learned if data sheet says mosfet max amp is 60s that it not true only for very short pulse. Mosfet package is what determines the real max amps mosfet can handle. My P55NF06 can do 34a max continuous, 35a mosfets explode. Mosfets do not even get warm at 34a I think the 10k resistors are the trick to not wasting power. Power supply is 1400 watts I still have room to double the power at the work coil if I can find mosfets that will do 1400 watts. At the moment 23.2v x 25a = 580 watts. This circuit is running much more efficnent than it did in the past. Any suggestions how to make the circuit work better?

Last edited: