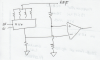

I intend to use a single A/D channel with one InAmp and one Wheatstone bridge in quarter-configuration at its input as AFE for an array of multiple strain gauges with nominal resistance of 1kΩ. Obviously, this needs to be implemented with a multiplexer (only solid-state solution is acceptable). However, I am concerned of the error that will be introduced by the on-resistance of the MUX. Do you think that this issue is important? As far as I have seen in the market, the lowest on-resistance that can be selected is 300mΩ.