So I have a nurse call system that I need to modify. Currently, when a room call is activated the control panel sounds an audible alarm and illuminates a small 2 volt LED. Each patients room has a call button in both the room and bathroom, and it illuminates a different LED on the control panel for room or bathroom. I want to use the power off the 2V LED as a signal/ trigger to illuminate a LED number to the corresponding room (simple 3D printed plastic backlit number). The purpose for this so that you could see from a distance what room has called and not have to walk right up to the control panel.

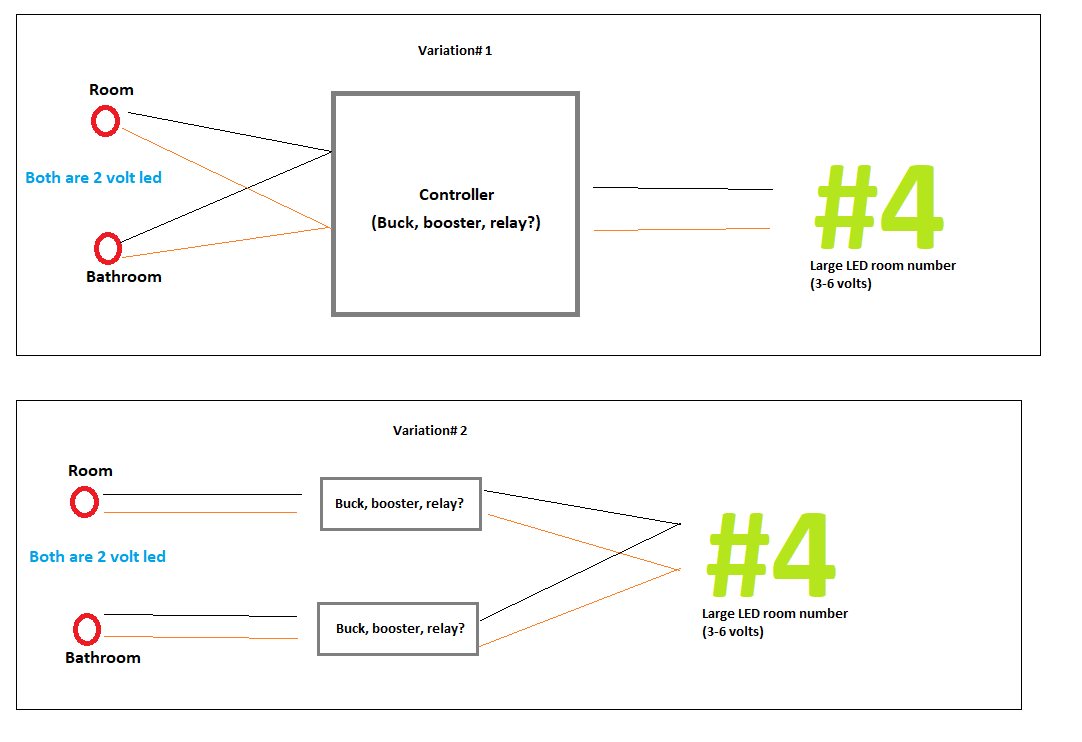

I have come up with 2 variations for how I could wire this and need some help to go further. The sketch helps to explain alot.

- Each variation needs to use abuck converter? booster? or relay? to go from the 2V input signal to power the LED number which will be 3-6V.

- Are there other options on a control module?

Variation #1

The signal input wires would join to the same terminals on whatever controller I am using. If the room call 2V LED is activated it would also send power back to the bathroom LED, which will send unwanted power back into the control panel and may cause damage. So the signal input wires would need diodes(?) On every wire? Or just the positive wire?

With this setup I would only need to use 1 control module per room, but have to install diodes.

Variation #2

The output wires would terminate on the number LED. If the room call is activated it would also send power back to the bathroom controller. I would also have to install diodes here, or Depending on what controller I am using it may not be needed. For example a 2 pole mini relay? If that exists?

With this setup I would need to use 2 control modules per room, and not need diodes with a relay?

I need to do this for 8 rooms so the amount of work is something that I am keeping in mind.

The large LED room number (#4 in pic below) is not a display of any kind. Its a plastic 3D printed piece with LED's inside of it that light it up.

I will be using an external power supply for these LED numbers, not getting power from the panel itself.

Thanks in advance!!

I have come up with 2 variations for how I could wire this and need some help to go further. The sketch helps to explain alot.

- Each variation needs to use a

- Are there other options on a control module?

Variation #1

The signal input wires would join to the same terminals on whatever controller I am using. If the room call 2V LED is activated it would also send power back to the bathroom LED, which will send unwanted power back into the control panel and may cause damage. So the signal input wires would need diodes(?) On every wire? Or just the positive wire?

With this setup I would only need to use 1 control module per room, but have to install diodes.

Variation #2

The output wires would terminate on the number LED. If the room call is activated it would also send power back to the bathroom controller. I would also have to install diodes here, or Depending on what controller I am using it may not be needed. For example a 2 pole mini relay? If that exists?

With this setup I would need to use 2 control modules per room, and not need diodes with a relay?

I need to do this for 8 rooms so the amount of work is something that I am keeping in mind.

The large LED room number (#4 in pic below) is not a display of any kind. Its a plastic 3D printed piece with LED's inside of it that light it up.

I will be using an external power supply for these LED numbers, not getting power from the panel itself.

Thanks in advance!!

Last edited: