Krumlink

New Member

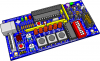

For a robot idea I was thinking of putting a junebug on board as the controller. The only problem would be the power supply, as a USB cable being dragged would not look so cool. I then examined the headers on the junebug and conveniently found a +5V next to GND. I then build a simple PWR and header connector, connect it to a 750M05C 5VDC LDO regulator with the proper capacitors, and a 6AA battery pack. Power is good to go! I plug it in and only realize it is going to power the target. No good. I then remember bill posting about shorting the U5V to the +5V to bypass the MOSFET's to power targets possibly drawing more than 100ma. I short them out and the rest of the junebug is powered. But a wire is going to look tacky, so I solder and glue on a shorting switch. I then machine out a nice looking lexan base with standoffs, which the batteries tightly fit. Success! I now have a portable Junebug!

Pictures:

001: General picture.

002: Voltage regulation coated in hot glue to prevent something.

003: Fuzzy front angle picture

004: Junebug plugged in and working

Comments? Questions?

Pictures:

001: General picture.

002: Voltage regulation coated in hot glue to prevent something.

003: Fuzzy front angle picture

004: Junebug plugged in and working

Comments? Questions?