strokedmaro

New Member

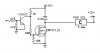

Attached is a design that was intended to simply turn the 5 ohm solenoid on and off. Would it be possible to pulse this with a PIC? I'm trying to get information on the duty cycle and frequency but I'm unsure if the hardware I used to build it is capable? What would you say is the maximum possible frequency this circuit could reliably pulse at? Currently I'm guessing no more than 100Hz is required but again I'm trying to find out an exact number....THANKS!