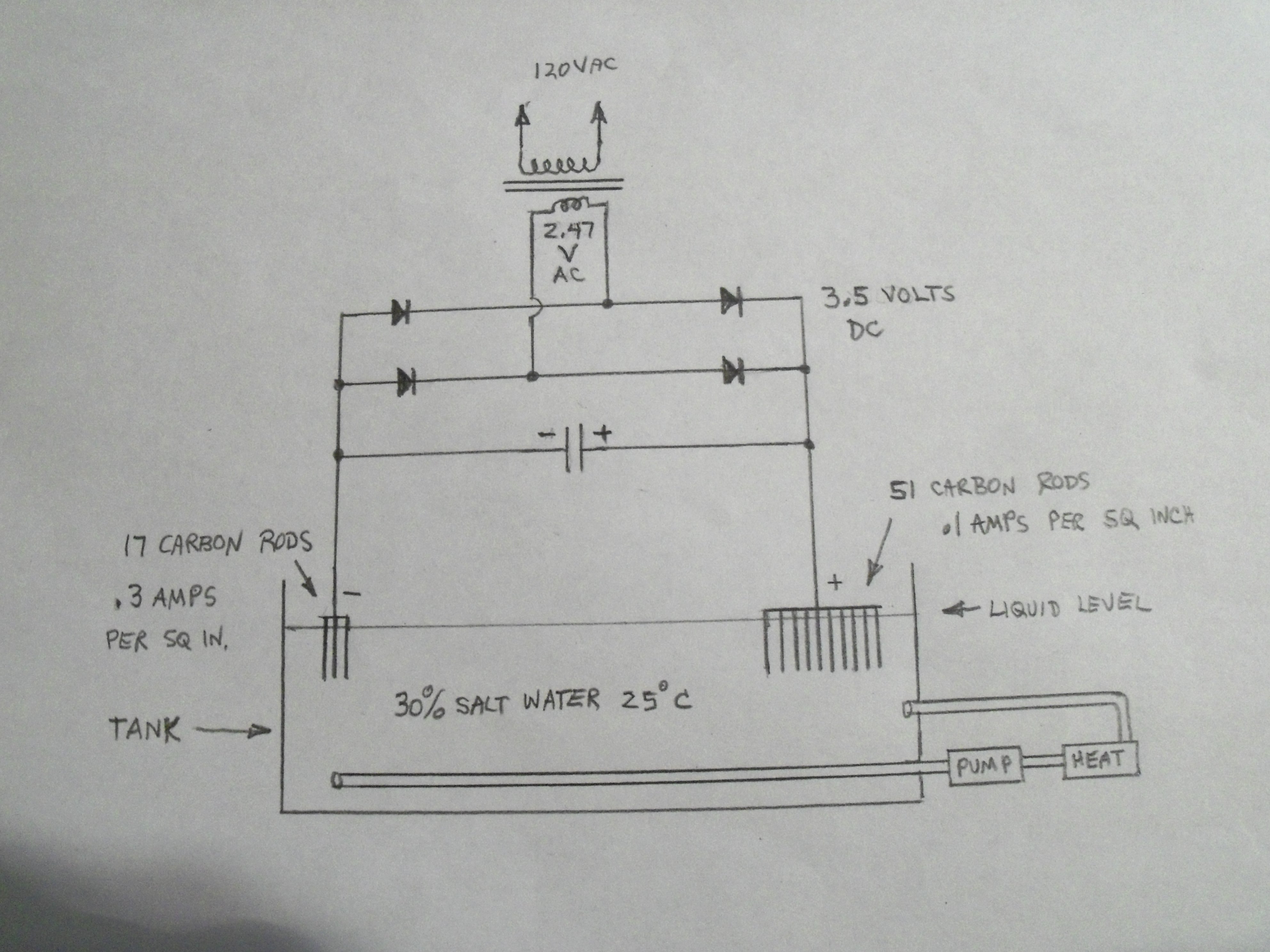

I drew my circuit for the 71 carbon rods that I have it turns out to be only 26 watts. I need to order titanium plates so I can make full use of a 1400 watt transformer. Circuit is 3.5 volts DC. Amps on the cathode plates .1 amp per sq in. I need to buy enough titanium to make the math work out. Diodes should be 10 volts 400 amps. My industrial chemistry book says 3KW for every lb of salt in water and water is 30% salt at 25 degree C. Before I do more math for surface area of titanium plates and tank size I need to know what diodes are available?

How much voltage drop is there on a diode? Is that on the datasheet?

How much voltage drop is there on a diode? Is that on the datasheet?

Last edited: