I am building a PIC device that is going to meassure the RPM on my motorcycle.

I have made one prototype that is using the signal to the original RPM meter (what is the engligh name for that).

That one works great, but i want to make a device that do not need any physical contact with the bikes, electrical system.

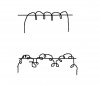

I want to get the signal from the cable from the ignition coil to the spark plug. I want a contactless sensor. I thought that there must be a rather big electromagnetical field when igniting.

So how can i do? I want to make it easy to use.

Look at my mspaint picture. Which one of those methods should i use? Would some of them work at all?

How how can i expect the output to be? Guess it depends on how many rotations i make.

I hope you understand my english :wink:

I have made one prototype that is using the signal to the original RPM meter (what is the engligh name for that).

That one works great, but i want to make a device that do not need any physical contact with the bikes, electrical system.

I want to get the signal from the cable from the ignition coil to the spark plug. I want a contactless sensor. I thought that there must be a rather big electromagnetical field when igniting.

So how can i do? I want to make it easy to use.

Look at my mspaint picture. Which one of those methods should i use? Would some of them work at all?

How how can i expect the output to be? Guess it depends on how many rotations i make.

I hope you understand my english :wink: