MrDEB

Well-Known Member

interrupt 2x instead of 1x

Been hacking this for a day and a half trying to configure to get one interrupt to enable LED on portA.5 but getting two cycles through code instead of one.

When I started I was getting 3x.

I only need 1x

Also thinking I should get a lower current draw during SLEEP. Presently drawing 4,2ma during sleep.

Been hacking this for a day and a half trying to configure to get one interrupt to enable LED on portA.5 but getting two cycles through code instead of one.

When I started I was getting 3x.

I only need 1x

Also thinking I should get a lower current draw during SLEEP. Presently drawing 4,2ma during sleep.

Code:

{

*****************************************************************************

* Name : UNTITLED.BAS *

* Author : Doug *

* Notice : Copyright (c) 2013 [select VIEW...EDITOR OPTIONS] *

* : All Rights Reserved *

* Date : 1/4/2013 *

* Version : 1.0 *

* Notes : had 3x but now 2x. Only need 1x *

* : *

*****************************************************************************

}

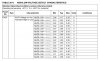

Device = 18F2420

Clock = 8

Include "InternalOscillator.bas"

Dim RBIF As INTCON.0 //port change interupt flag

Dim RBIE As INTCON.3 //port change interupt enable

Dim LED1 As PORTA.5

Dim led2 As PORTA.3

'xxxxxxxxxxxxxxxxxxxx

'interrupt

'xxxxxxxxxxxxxxxxxxxxx

Interrupt PORTB_Change()

// Save(0) // Save the system variables

If RBIF = 1 Then // Check if the interrupt was a PORTB change

// RBIF = 0 ' moved to end

WREG = PORTB // Be sure to read the contents of PORTB to

// clear the mismatch

// PORTB 7:4 has changed

LED1 = 0

DelayMS(5000)

Toggle (LED1)

DelayMS(500)

EndIf

RBIF = 0 // clear flag this changed from 3x to 2x

// Restore // Restore the system variables

End Interrupt

Sub PORTB_Interrupts(Control As Boolean) // Small routine to enable/disable PORTB Interrupts.

If Control = True

Then

RBIE = 1 // interrupt enable bit

Enable(PORTB_Change)

Else //

RBIE = 0 //

Disable(PORTB_Change) //

EndIf //

End Sub

Inline Sub Sleep()

Asm

Sleep

End Asm

End Sub

// Start Of Program...

TRISB = %11110000 // Make PORTB7:4 all inputs

//TRISC = %00000000 // Make PORTC all outputs

While True // Infinite loop

PORTB_Interrupts(true) // Enable PORTB interrupts

Sleep // Put the PIC to sleep and wait for a change

// on PORTB 7:4

Wend