Thoughtsprocket

New Member

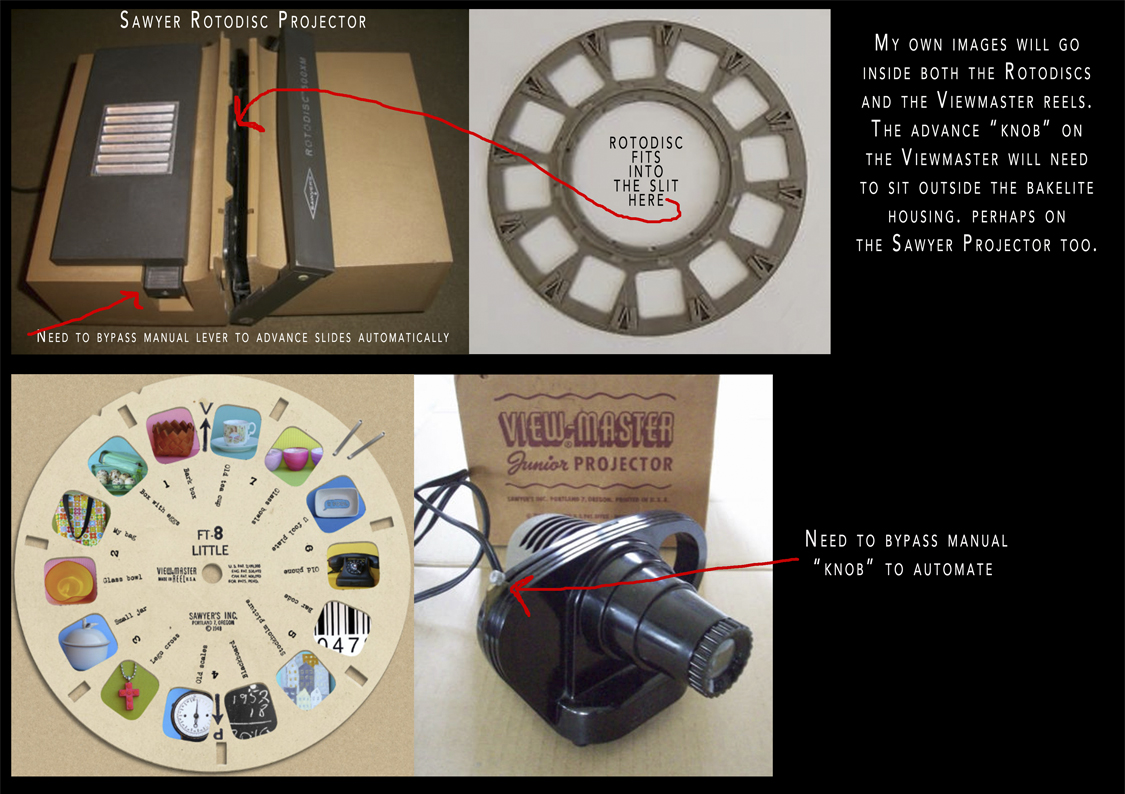

Greetings Everyone. I'm a graduate student of interdisciplinary art who is fairly digital savvy, but not electrically savvy when it comes to hacking analogue devices. I need advice on how I can automate a vintage projector. The slides are advanced manually. I need them to advance automatically. Perhaps some of you might ask why even use a vintage slide projector at all with all of the new technology available to us today. Good question! Well, my graduate work is focused on memory, so the slide projectors are a way to consider the past as ever present. I want to create two banks of projectors. One bank of projectors will be Sawyer 2 x2 Rotodisc Projectors with rotodiscs filled with my own 35mm work. The other bank will be made up of Viewmaster Projectors hat will project images of my own contemporary work. I am curious to know how to automate these kinds of projectors, and how to "link" them together. Thus far all of my art installation projections are the usual large wall projections or projections onto objects using Epson projectors with Macbook Pro laptops. I have never used Arduino or Max. Is this the way I should go with these projects or is there some other more rudimentary electrical way to do this? Any answers are greatly appreciated. I'd be very happy at this point just to learn how to do the most basic automation.