rodrigopoeta

New Member

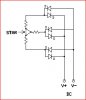

I have a head VCR and I'm intending to use it for power generation and wind generator. However this head has a circuit board to which are attached several coils. At the top of the head board you can see the welds of these coils. Altogether has 6 parts welded. But at the bottom there are 12 coils. The question is In which way should I weld the top to have a three-phase or biphasic? Should I weld the wires directly in the welds of the coils? How to weld? Is it possible to come up with a system in which I have only two wires at the end?

I posted some pictures to help. There is one picture of the top of the VCR Board Head that I put the numbers where the welds are in order to facilitate the explanation.

I thank everyone's help!

I posted some pictures to help. There is one picture of the top of the VCR Board Head that I put the numbers where the welds are in order to facilitate the explanation.

I thank everyone's help!