Hi I've just got my first oscilloscope (digital) to help me learn more about pcb repairs.

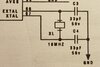

I'm looking to test the resonator clock frequency in the diagram. Is there an accurate way to test or calculate the 16mhz frequency? I can test the oscillating caps and I get 2.9khz. I'm missing a piece of the puzzle somewhere.

Most of these boards are 20+ years old so it would be great to validate the cpu's a correct on what's coming out of the extal/xtal pins aswell if I can.

What should I do?

Huge thanks.

I'm looking to test the resonator clock frequency in the diagram. Is there an accurate way to test or calculate the 16mhz frequency? I can test the oscillating caps and I get 2.9khz. I'm missing a piece of the puzzle somewhere.

Most of these boards are 20+ years old so it would be great to validate the cpu's a correct on what's coming out of the extal/xtal pins aswell if I can.

What should I do?

Huge thanks.