Hello all,

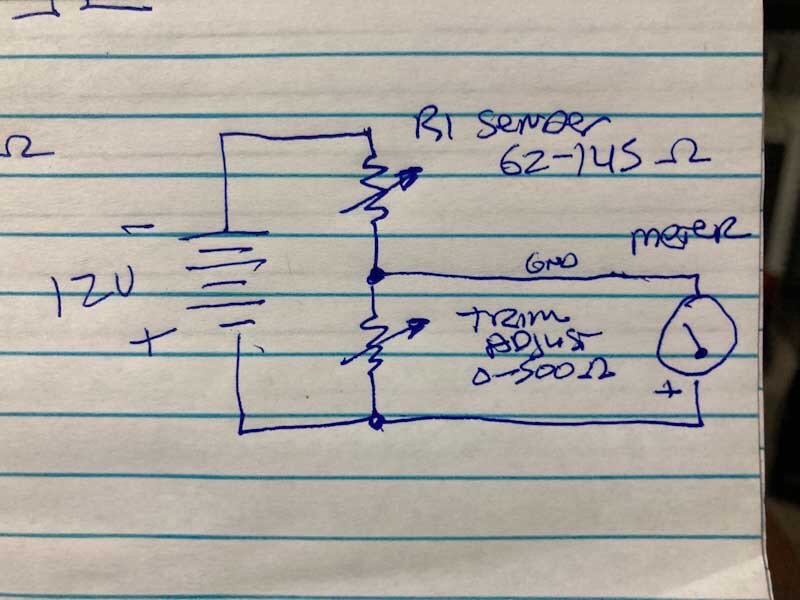

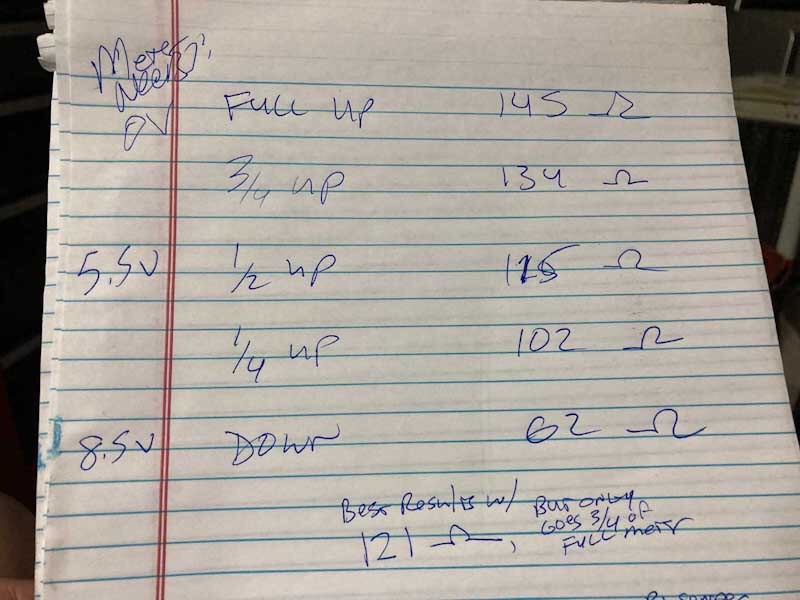

I am trying to get a boat trim sensor and meter configured, this is a 12 V DC system. The sender that attaches to the trim unit is a potientometer, and shows 145 ohms at “full up travel”, and 62 ohms at full down. The meter requires 0v at full up and 8.5 volts at full down.

I created a voltage divider with a 500 ohm pot for adjusting the range, and I get the best results at about 122 ohms, but I am only getting about 60% of the indication on the trim meter (basically a voltmeter).

Somehow I need to increase the scaling, as I am stuck with the sender on the pot. Not sure how to proceed. TIA.

I am trying to get a boat trim sensor and meter configured, this is a 12 V DC system. The sender that attaches to the trim unit is a potientometer, and shows 145 ohms at “full up travel”, and 62 ohms at full down. The meter requires 0v at full up and 8.5 volts at full down.

I created a voltage divider with a 500 ohm pot for adjusting the range, and I get the best results at about 122 ohms, but I am only getting about 60% of the indication on the trim meter (basically a voltmeter).

Somehow I need to increase the scaling, as I am stuck with the sender on the pot. Not sure how to proceed. TIA.