Hi all,

I'm new to this forum and hope that you can help me. I'm in the process of building a control cabinet for my home brewery. The brewery consists of three heating elements (3500W) but I only have available two 16A power feeds (220V, living in Norway).

The heating elements are controlled by 4 contactors, K1, K2, K3 and K4, where K2 & K3 are for Heater 2. To control the 4 contactor I have three switches, on my drawing showed as NO, but can I can add more NC or NO to these.

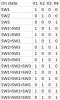

I've created a logic on how this should work, with switching sequence in left column. The main areas of concern is that K1&K2 must never activate at the same time. This also applies to K2&K3 and K3&K4. All the contactor have additional 1xNO and 1xNC that can be used. If needed I can also add more relays. The control voltage for the contactors are 24VDC.

Attached is also a ladder diagram showing my thinking, but I'm stuck. No matter how hard I try I'm not able to solve this, it has been too long since my electronic exams.

Maybe not a very good description, but I hope it's understandable.

I'm very grateful for any help, my brewing of beer depends on this

I'm new to this forum and hope that you can help me. I'm in the process of building a control cabinet for my home brewery. The brewery consists of three heating elements (3500W) but I only have available two 16A power feeds (220V, living in Norway).

The heating elements are controlled by 4 contactors, K1, K2, K3 and K4, where K2 & K3 are for Heater 2. To control the 4 contactor I have three switches, on my drawing showed as NO, but can I can add more NC or NO to these.

I've created a logic on how this should work, with switching sequence in left column. The main areas of concern is that K1&K2 must never activate at the same time. This also applies to K2&K3 and K3&K4. All the contactor have additional 1xNO and 1xNC that can be used. If needed I can also add more relays. The control voltage for the contactors are 24VDC.

Attached is also a ladder diagram showing my thinking, but I'm stuck. No matter how hard I try I'm not able to solve this, it has been too long since my electronic exams.

Maybe not a very good description, but I hope it's understandable.

I'm very grateful for any help, my brewing of beer depends on this