Hi,

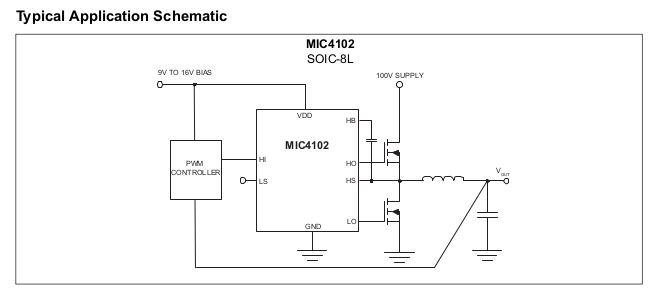

I'm reading up on several driver designs which could simplify my application. Originally I'd created a sync buck design via a PIC driving two FET's (high/low). Unfortunately I forgot I'd need some method of detecting current flow through the inductor to ensure the load (which is capacitive) wasn't discharging. I'm working with up to 100V hence why I haven't gone integrated.

One chip that has caught my eye is the MIC4102. It specifically states in the documentation that it'll detect when HS is positive to GND and prevent LO from switching on. Is this is the case with all half bridge drivers?

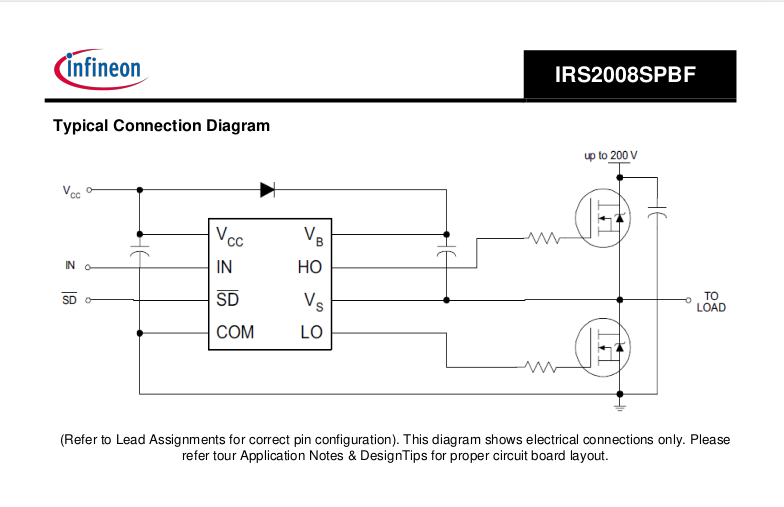

The reason I ask is the IRS2008 is much cheaper (< 1/4 the price). I'm wondering why, such as whether the IRS2008 is much slower which makes it less suitable for a buck.

Final question, would two of these (aka a full bridge rectifier) give active rectification? That is, can the load be AC and positive/negative to Vs, or is Vs always floating? (If it is I don't know how it monitors it relative to ground).

Thanks,

Andrew

I'm reading up on several driver designs which could simplify my application. Originally I'd created a sync buck design via a PIC driving two FET's (high/low). Unfortunately I forgot I'd need some method of detecting current flow through the inductor to ensure the load (which is capacitive) wasn't discharging. I'm working with up to 100V hence why I haven't gone integrated.

One chip that has caught my eye is the MIC4102. It specifically states in the documentation that it'll detect when HS is positive to GND and prevent LO from switching on. Is this is the case with all half bridge drivers?

The reason I ask is the IRS2008 is much cheaper (< 1/4 the price). I'm wondering why, such as whether the IRS2008 is much slower which makes it less suitable for a buck.

Final question, would two of these (aka a full bridge rectifier) give active rectification? That is, can the load be AC and positive/negative to Vs, or is Vs always floating? (If it is I don't know how it monitors it relative to ground).

Thanks,

Andrew