cartoonwally

New Member

Hey guys,

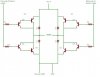

I've seen a few of the H-bridges designed by members of the forum lerking around but i wanted to see whether you thought that this one would work. I am driving the input with 4.8->6V from a servo (where the motor on the servo usually connects) and the ground from the servo circuit runs to the bottom of there. The thing i'd like to know is whether you think this circuit, and the circuit components ive chosen will work.

Q1,Q2,Q7,Q9 TIP2955 60V 15A PNP Transistor

https://www.electro-tech-online.com/custompdfs/2008/02/TIP2955.pdf

Q3,Q4,Q5,Q6 BC547 50V 100mA NPN Transistor

https://www.electro-tech-online.com/custompdfs/2008/02/BC547.pdf

R1->R4 1k0 resistor

Circuit is attached

Btw i am aware of some of the bugs i.e floating inputs...

Also, are those diodes imperative to the design? what do they actually do? and do i really need them? (this may be a really stupid qn, flame suit on)

I've seen a few of the H-bridges designed by members of the forum lerking around but i wanted to see whether you thought that this one would work. I am driving the input with 4.8->6V from a servo (where the motor on the servo usually connects) and the ground from the servo circuit runs to the bottom of there. The thing i'd like to know is whether you think this circuit, and the circuit components ive chosen will work.

Q1,Q2,Q7,Q9 TIP2955 60V 15A PNP Transistor

https://www.electro-tech-online.com/custompdfs/2008/02/TIP2955.pdf

Q3,Q4,Q5,Q6 BC547 50V 100mA NPN Transistor

https://www.electro-tech-online.com/custompdfs/2008/02/BC547.pdf

R1->R4 1k0 resistor

Circuit is attached

Btw i am aware of some of the bugs i.e floating inputs...

Also, are those diodes imperative to the design? what do they actually do? and do i really need them? (this may be a really stupid qn, flame suit on)