Hi, Hello everyone

I am glad Google brought me here. Sooo many awesome ideas and discussions being shared that I almost forgot the reason for becoming a member.

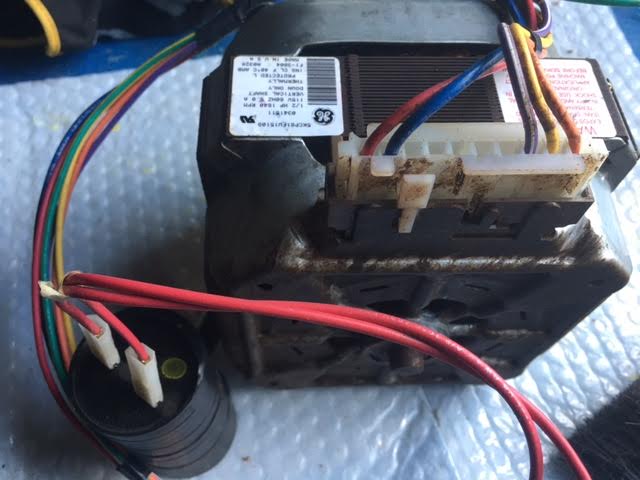

I need to power up abrushless AC ( thank you SHORTBUS= )120v induction motor. It's a pull from an older washing machine. The powering harness has five connectors in two distinct groups ( see picture please - and I apologize for the crud on the motor ). Here are my readings with multi meter:

RED / Purple .... ( continuity ) 0.4 ohm

Blue / Yellow .... ( continuity ) 2.8 ohm

Blue / Orange .... ( continuity ) 2.8 ohm

Orange / Yellow .... ( continuity ) 0.4 ohm

( RED is connected to a starter CAP )

At the first stage I need to test the motor for functionality and just make it run ( 120v ) and then if the motor has the capability of two speeds, I like to wire it with switches for running it at desired available speeds.

Any help will be greatly appreciated

I am glad Google brought me here. Sooo many awesome ideas and discussions being shared that I almost forgot the reason for becoming a member.

I need to power up a

RED / Purple .... ( continuity ) 0.4 ohm

Blue / Yellow .... ( continuity ) 2.8 ohm

Blue / Orange .... ( continuity ) 2.8 ohm

Orange / Yellow .... ( continuity ) 0.4 ohm

( RED is connected to a starter CAP )

At the first stage I need to test the motor for functionality and just make it run ( 120v ) and then if the motor has the capability of two speeds, I like to wire it with switches for running it at desired available speeds.

Any help will be greatly appreciated

Last edited: