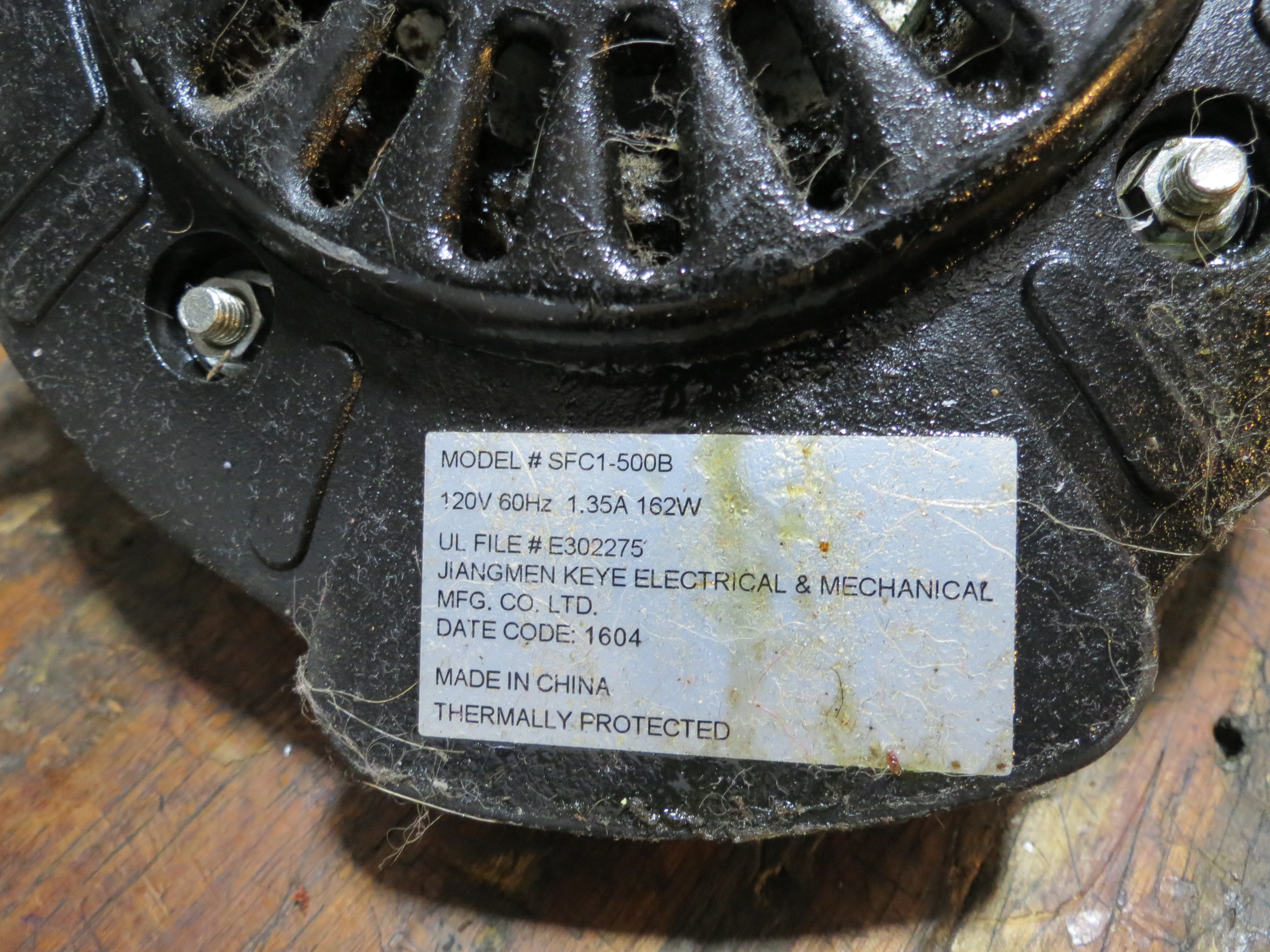

I have the following fan motor model # SFC1-500B, 120V 60HZ 1.35A 162W. I am trying to figure out how to repair it. This is a learning project and not sure how to get past this part.

The red color wire has no continuity getting to the windings. I checked it from one of the prongs on the power cord. Th the power cord is connected to a red wire that goes to a white wire that goes to the windings. There is continuity to the white wire as you can see under the insulation that disrepair into the windings. I check the winding to see if there is continuity and I get none. I should be able to touch it with the multi-meter and get low resistance correct?

How do I check to see if the coil can receive power from the power cord? This seems like the most obvious way. If there a copper wire broken from the white wire located under the insulation?

The red color wire has no continuity getting to the windings. I checked it from one of the prongs on the power cord. Th the power cord is connected to a red wire that goes to a white wire that goes to the windings. There is continuity to the white wire as you can see under the insulation that disrepair into the windings. I check the winding to see if there is continuity and I get none. I should be able to touch it with the multi-meter and get low resistance correct?

How do I check to see if the coil can receive power from the power cord? This seems like the most obvious way. If there a copper wire broken from the white wire located under the insulation?