Working with 230V 50Hz AC House electrics.

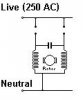

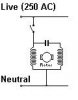

Got a 230V 10A DC motor I’m connecting to a fan for an air conditioning unit in my house. For the conversion from AC to DC I’m using a bridge rectifier and need some form of control for the speed of the motor so I can minimise noise. The way I see it if I connect a potentiometer to the DC power in to the motor I can august the speed of the motor? :?: :?: :?:

I’m sure there are some other components I need to connect? Anyone make a quick wiring diagram of the bridge rectifier and stuff, my dad and I would be well pleased

Got a 230V 10A DC motor I’m connecting to a fan for an air conditioning unit in my house. For the conversion from AC to DC I’m using a bridge rectifier and need some form of control for the speed of the motor so I can minimise noise. The way I see it if I connect a potentiometer to the DC power in to the motor I can august the speed of the motor? :?: :?: :?:

I’m sure there are some other components I need to connect? Anyone make a quick wiring diagram of the bridge rectifier and stuff, my dad and I would be well pleased