Iawia

Member

Hi All,

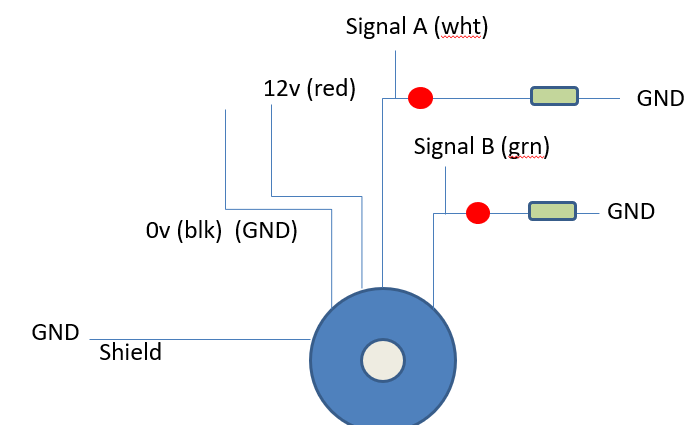

I have a question on wiring a 4-wire rotary encoder. I have searched diagrams for it and it seems like it is hooked up correctly. I cannot find a lot of information about the output voltage. Is it 5v? My input for can be between 5-24v, I have attempted to probe the output voltage with a meter and get ~1v. What am I doing wrong, can an LED (red dots in diagram) be driven by the output of the encoder? I am also fine with just probing with the meter. Thanks in advance.

Rotary Encoder

5-24v input

4-wire

TYPE LPD3806-360BM-G5-24C

Shaft 6mm

(No company name)

I have a question on wiring a 4-wire rotary encoder. I have searched diagrams for it and it seems like it is hooked up correctly. I cannot find a lot of information about the output voltage. Is it 5v? My input for can be between 5-24v, I have attempted to probe the output voltage with a meter and get ~1v. What am I doing wrong, can an LED (red dots in diagram) be driven by the output of the encoder? I am also fine with just probing with the meter. Thanks in advance.

Rotary Encoder

5-24v input

4-wire

TYPE LPD3806-360BM-G5-24C

Shaft 6mm

(No company name)