MrDEB

Well-Known Member

well I finally got around to using the laminator I purchased from Pulsar,

got to worring that I was doing something wrong. The tech support is GREAT, lots of info from the company.

I printed boards onto the transfer paper using print density 5 - a must for quality

turned on laminator, light comes on after 5 minutes. ran board through the laminator-MISTAKE!!

Run through the laminator AFTER 20 miniutes of warm up

Have a pan of water to cool board immedietly after passing board through twice-once from each end, the narrow width.

MISTAKES-not enough laminator warm up

did not cool immediately

when using the green ttf paper use the high setting.

The boards came out GREAT compared to using an iron

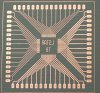

for etching - 1 part muratic acid and 2 parts hydrogen peroxide. cheaper, easier and seems to work just as fast.as the brown etching gunk.In the scan I havn't cleaned or cut square the boards yet.

experimented with an adapter I made for the Dremel tool to use in a drill press. Worked really well.

going with SMT as Pulsar told me they are working on a hot plate or ? that you don't use a soldering iron to use smd

got to worring that I was doing something wrong. The tech support is GREAT, lots of info from the company.

I printed boards onto the transfer paper using print density 5 - a must for quality

turned on laminator, light comes on after 5 minutes. ran board through the laminator-MISTAKE!!

Run through the laminator AFTER 20 miniutes of warm up

Have a pan of water to cool board immedietly after passing board through twice-once from each end, the narrow width.

MISTAKES-not enough laminator warm up

did not cool immediately

when using the green ttf paper use the high setting.

The boards came out GREAT compared to using an iron

for etching - 1 part muratic acid and 2 parts hydrogen peroxide. cheaper, easier and seems to work just as fast.as the brown etching gunk.In the scan I havn't cleaned or cut square the boards yet.

experimented with an adapter I made for the Dremel tool to use in a drill press. Worked really well.

going with SMT as Pulsar told me they are working on a hot plate or ? that you don't use a soldering iron to use smd