DerStrom8

Super Moderator

Hi all, I've got a pretty simple question but have yet to find a solution.

I am currently working on a project with a fixture, and a universal connector on the output. The connector consists of a digital output and a digital input (among other things). Mating to the connector are two different daughter boards. Only one can be plugged in at a time but they need to connect to the same header. The difference between the two separate boards is that the positions of the input pin and the output pin are swapped. In order to connect them properly I have a relay that switches the position of the data lines on the main board before it gets to the output connector. The relay is switched based on which board is supposed to be plugged in. I realize this may be a bit difficult to understand, but please bear with me.

The problem is that the relay may not always be right. Worst case scenario would be that it's switched the wrong direction, connecting two inputs together (not a huge deal) and two outputs together (potentially damaging the main board or to the daughter boards).

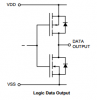

I am looking for a way to sense if two outputs are connected to each other. The output on the daughter board is driven by the input, so if the input and output lines are swapped then the output of the daughter board will be "dead". Based on the datasheet, this is the internal schematic of the output for the daughter board:

If the wrong daughter board is connected, then the main board will be directly driving the "DATA OUTPUT" pin of the above circuit. Since I don't have any information about the FETs, I don't know how much current they can handle. From what I'm seeing in the datasheet for the component (It's the Microchip HV5623: **broken link removed** ) the output is active-high, meaning if the input isn't being driven, then the output would be pulled to ground. If a voltage is present at the DATA OUTPUT pin, then it would be shorted through the FET potentially causing damage.

Here's a very simple diagram showing the problem. Note the polarity dots:

Here, the main board is shown on the left and the daughter boards are shown on the right. The top image shows if the correct daughter board is connected. The bottom one shows if the wrong one is connected (This is a simplified drawing that doesn't show the relay or any of the other circuitry. It's just to get a point across).

Does anyone have any thoughts of how this could be sensed? I cannot change the main board or the daughter boards--It would have to be yet another board that plugs into the main board, that the daughter boards can plug into (this third board is the one that has the relay on it). The solution must be able to detect the reversed input/output lines very quickly to prevent damage to the chips. Once again, if the wrong board is plugged in then its output line would be dead (not driven) so it must be able to sense over-current, without a lot of current sense circuitry. I had considered using an op-amp to sense the current through a shunt resistor, then feed it to a comparator that sends a signal back to the main board. This signal would say whether there is too much current, but that would have too many delays and probably wouldn't be able to cut power quickly enough to prevent damage to the chip.

Any ideas?

Thanks,

matt

I am currently working on a project with a fixture, and a universal connector on the output. The connector consists of a digital output and a digital input (among other things). Mating to the connector are two different daughter boards. Only one can be plugged in at a time but they need to connect to the same header. The difference between the two separate boards is that the positions of the input pin and the output pin are swapped. In order to connect them properly I have a relay that switches the position of the data lines on the main board before it gets to the output connector. The relay is switched based on which board is supposed to be plugged in. I realize this may be a bit difficult to understand, but please bear with me.

The problem is that the relay may not always be right. Worst case scenario would be that it's switched the wrong direction, connecting two inputs together (not a huge deal) and two outputs together (potentially damaging the main board or to the daughter boards).

I am looking for a way to sense if two outputs are connected to each other. The output on the daughter board is driven by the input, so if the input and output lines are swapped then the output of the daughter board will be "dead". Based on the datasheet, this is the internal schematic of the output for the daughter board:

If the wrong daughter board is connected, then the main board will be directly driving the "DATA OUTPUT" pin of the above circuit. Since I don't have any information about the FETs, I don't know how much current they can handle. From what I'm seeing in the datasheet for the component (It's the Microchip HV5623: **broken link removed** ) the output is active-high, meaning if the input isn't being driven, then the output would be pulled to ground. If a voltage is present at the DATA OUTPUT pin, then it would be shorted through the FET potentially causing damage.

Here's a very simple diagram showing the problem. Note the polarity dots:

Here, the main board is shown on the left and the daughter boards are shown on the right. The top image shows if the correct daughter board is connected. The bottom one shows if the wrong one is connected (This is a simplified drawing that doesn't show the relay or any of the other circuitry. It's just to get a point across).

Does anyone have any thoughts of how this could be sensed? I cannot change the main board or the daughter boards--It would have to be yet another board that plugs into the main board, that the daughter boards can plug into (this third board is the one that has the relay on it). The solution must be able to detect the reversed input/output lines very quickly to prevent damage to the chips. Once again, if the wrong board is plugged in then its output line would be dead (not driven) so it must be able to sense over-current, without a lot of current sense circuitry. I had considered using an op-amp to sense the current through a shunt resistor, then feed it to a comparator that sends a signal back to the main board. This signal would say whether there is too much current, but that would have too many delays and probably wouldn't be able to cut power quickly enough to prevent damage to the chip.

Any ideas?

Thanks,

matt