Hi!

First of all, since this is my first post, let me introduce myself. I'm Ben, 37yo, and English is not my first language so I will try to be as specific and precise as I can.

I have no particular knowledge in micro electronics, I try to learn as much as I can, but this time, I'm afraid I can't go further on my project without any help.

My project is a game I made for my kids who love to play indians, with their bow and sticky arrows. I made 10 targets (slaves), using arduinos, shock sensors, LEDs and NRF modules (and the master target with an added bluetooth module), that I spread througout the woods I have in my backyard. The kids run around, hit the targets and try to make the best score... The wireless design allows me to move the targets around and have them fairly spread out if I want to (up to 100 meters).

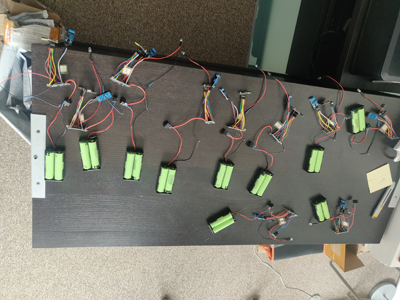

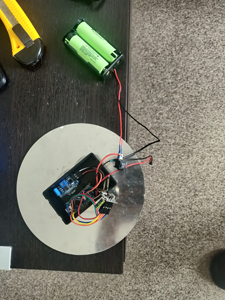

Here is how it looks, this picture was the first test I did with these (back in 2019), so I put them close together and just checked if everything was working correctly (I was fairly surprised when it did).

Here is my issue : I suck at soldering and this project took me weeks to assemble all the components. Also, the more the kids play with it, the more my targets "die" because a wire got loose and it is a real pain to find the issue and fix it. Yesterday, only 6 out of 10 were correctly working...

This is why I come to you with this question : how can I simplify my design as much as possible ?

My objective is to have as few components as necessary, and have a PCB made and all the components pre-assembled/soldered (or as many as possible), to reduce the possibility of poor soldering by myself, and save me time. A lot of time

Here are the components and the use I have of them :

- Arduino nano : it is just the brain, sending commands to other modules. I need a USB access to update the code if I need to.

- NRF24 - 2.4ghz radio module : used to communicate between slaves and master targets.

- SW420 - Shock sensor : detects a hit, sends a signal to the arduino that transmits the info to the NRF24 module

- LED - two colors, common cathode : lights green and red, depending on the game mode.

- JDY-31 - bluetooth module : only present on the master target, used to communicate with a PC (python) or Android (apk).

And this is the wiring :

A = Arduino

BT = JDY-31 BT module (Stat not used)

Shock = SW420 Shock Sensor

LED = Bicolor LED common Cathode

NRF = NRF24L01 (IRQ not used) - I have a 10uF capacitor added, as recommended in a few tutorials

A D6 ⇒ BT TX

A D7 ⇒ BT RX

A D5 ⇒ 220ohm resistor => LED 1

A D3 ⇒ 220ohm resistor => LED 2

A D4 ⇒ Schock DO

A D9 ⇒ NRF CE

A D10 ⇒ NRF CNS

A D11 ⇒ NRF MOSI

A D12 ⇒ NRF MISO

A D13 ⇒ NRF SCK

A 3.3V ⇒ NRF VCC + BT VCC

A 5V ⇒ Shock VCC

A VIN ⇒ Alim Positif

A Ground x2 ⇒ Alim Ground + BT Ground + NRF Ground + LED Ground + Shock Ground

I found tutorials on youtube showing how I could make a standalone arduino, using the chip and a few other components, but for the other modules, I have no idea how to proceed : their schematics are too complex for me and I don't know if I need all their components, for the basic use I have of them. I could maybe succeed with the shock sensor, it seems fairly simple, but I'm lost with the NRF and Bluetooth modules. I am also thinking of a possible improvement, by adding an external antenna to increase range and improve connectivity (trees are often blocking the RF signal, which is understandable considering the NRF module with its integrated antenna is stuck in a small project box, right next to other electronic components...)

Any help and advice with the design would be greatly appreciated!!

Thanks!

First of all, since this is my first post, let me introduce myself. I'm Ben, 37yo, and English is not my first language so I will try to be as specific and precise as I can.

I have no particular knowledge in micro electronics, I try to learn as much as I can, but this time, I'm afraid I can't go further on my project without any help.

My project is a game I made for my kids who love to play indians, with their bow and sticky arrows. I made 10 targets (slaves), using arduinos, shock sensors, LEDs and NRF modules (and the master target with an added bluetooth module), that I spread througout the woods I have in my backyard. The kids run around, hit the targets and try to make the best score... The wireless design allows me to move the targets around and have them fairly spread out if I want to (up to 100 meters).

Here is how it looks, this picture was the first test I did with these (back in 2019), so I put them close together and just checked if everything was working correctly (I was fairly surprised when it did).

Here is my issue : I suck at soldering and this project took me weeks to assemble all the components. Also, the more the kids play with it, the more my targets "die" because a wire got loose and it is a real pain to find the issue and fix it. Yesterday, only 6 out of 10 were correctly working...

This is why I come to you with this question : how can I simplify my design as much as possible ?

My objective is to have as few components as necessary, and have a PCB made and all the components pre-assembled/soldered (or as many as possible), to reduce the possibility of poor soldering by myself, and save me time. A lot of time

Here are the components and the use I have of them :

- Arduino nano : it is just the brain, sending commands to other modules. I need a USB access to update the code if I need to.

- NRF24 - 2.4ghz radio module : used to communicate between slaves and master targets.

- SW420 - Shock sensor : detects a hit, sends a signal to the arduino that transmits the info to the NRF24 module

- LED - two colors, common cathode : lights green and red, depending on the game mode.

- JDY-31 - bluetooth module : only present on the master target, used to communicate with a PC (python) or Android (apk).

And this is the wiring :

A = Arduino

BT = JDY-31 BT module (Stat not used)

Shock = SW420 Shock Sensor

LED = Bicolor LED common Cathode

NRF = NRF24L01 (IRQ not used) - I have a 10uF capacitor added, as recommended in a few tutorials

A D6 ⇒ BT TX

A D7 ⇒ BT RX

A D5 ⇒ 220ohm resistor => LED 1

A D3 ⇒ 220ohm resistor => LED 2

A D4 ⇒ Schock DO

A D9 ⇒ NRF CE

A D10 ⇒ NRF CNS

A D11 ⇒ NRF MOSI

A D12 ⇒ NRF MISO

A D13 ⇒ NRF SCK

A 3.3V ⇒ NRF VCC + BT VCC

A 5V ⇒ Shock VCC

A VIN ⇒ Alim Positif

A Ground x2 ⇒ Alim Ground + BT Ground + NRF Ground + LED Ground + Shock Ground

I found tutorials on youtube showing how I could make a standalone arduino, using the chip and a few other components, but for the other modules, I have no idea how to proceed : their schematics are too complex for me and I don't know if I need all their components, for the basic use I have of them. I could maybe succeed with the shock sensor, it seems fairly simple, but I'm lost with the NRF and Bluetooth modules. I am also thinking of a possible improvement, by adding an external antenna to increase range and improve connectivity (trees are often blocking the RF signal, which is understandable considering the NRF module with its integrated antenna is stuck in a small project box, right next to other electronic components...)

Any help and advice with the design would be greatly appreciated!!

Thanks!