Kerim

Member

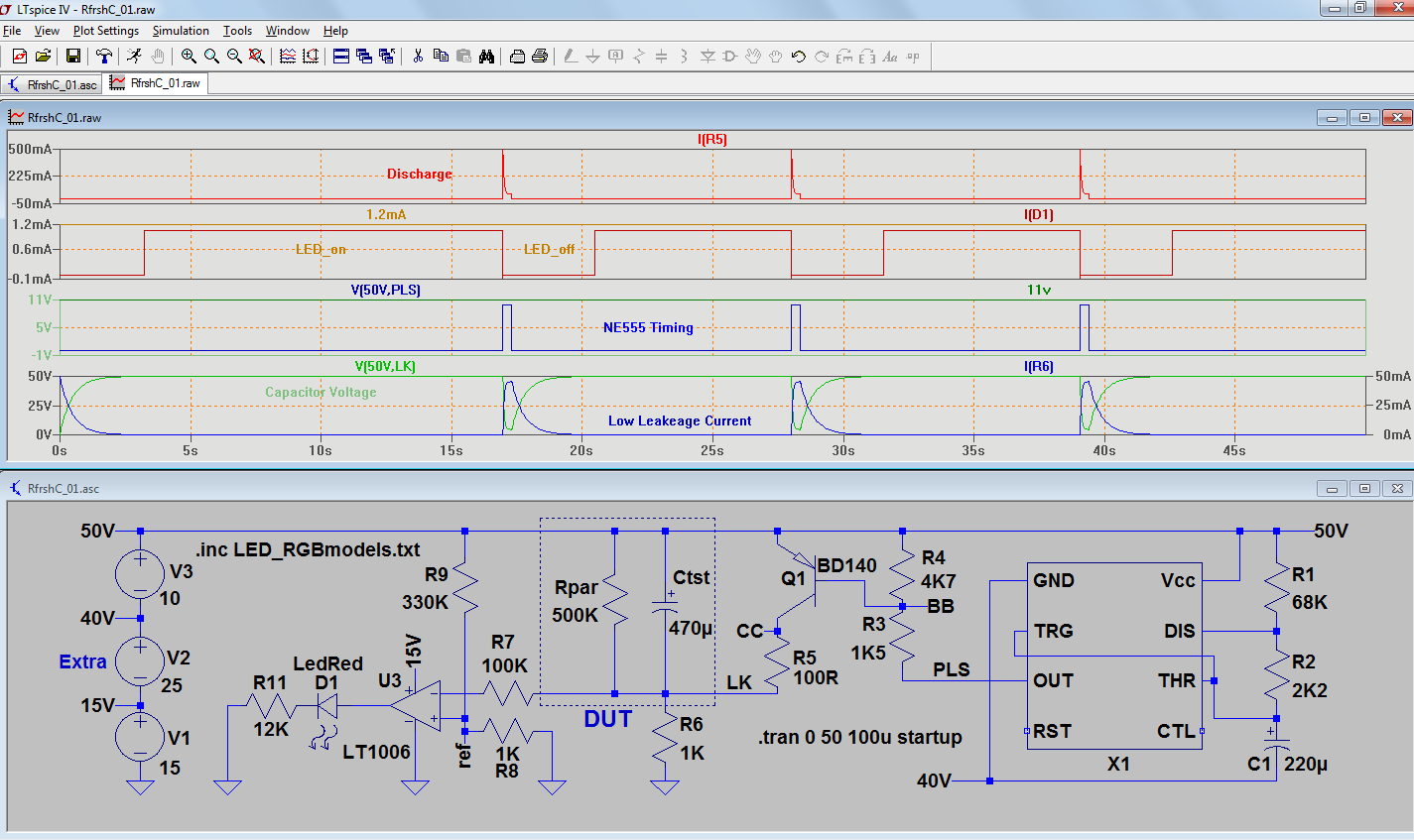

More than two decades ago, I bought many hundreds of 470u/50V capacitor then I forgot about them (the project for which I bought them was dropped). Lately, I needed them, but I found out that their leakage became rather high (low Rpar).

Usually, I refresh such capacitors manually. But since their number is rather big, I built the basic circuit below.

Here, the voltage applied on the capacitor under test (Ctst) is close to 50V. When its leakage current (represented by Rpar) becomes relatively low, the LED turns on, almost continuously. R5 limits the discharging current. The resistance of R9 determines the lowest leakage current that turns on the LED (the higher the resistance, the lower the leakage current to turn on the LED). There are three DC supplies which are connected in series. The first/bottom one (here 15V) supplies the opamp (LM358 or LM324 could be used). The third/top one (here 10V) supplies the timer NE555. The second/mid one (here 25V) is added to let the voltage on the capacitor under test be close to the voltage of interest (here 50V).

Sorry, since my private business is somehow paralyzed lately due to many factors, I try passing my free time by sharing here some of my works while I understand that no one around here may have a good reason to be interested in any of them.

Cheers,

Kerim

Usually, I refresh such capacitors manually. But since their number is rather big, I built the basic circuit below.

Here, the voltage applied on the capacitor under test (Ctst) is close to 50V. When its leakage current (represented by Rpar) becomes relatively low, the LED turns on, almost continuously. R5 limits the discharging current. The resistance of R9 determines the lowest leakage current that turns on the LED (the higher the resistance, the lower the leakage current to turn on the LED). There are three DC supplies which are connected in series. The first/bottom one (here 15V) supplies the opamp (LM358 or LM324 could be used). The third/top one (here 10V) supplies the timer NE555. The second/mid one (here 25V) is added to let the voltage on the capacitor under test be close to the voltage of interest (here 50V).

Sorry, since my private business is somehow paralyzed lately due to many factors, I try passing my free time by sharing here some of my works while I understand that no one around here may have a good reason to be interested in any of them.

Cheers,

Kerim